Breadcrumb

New FlexPack pilot plant available soon

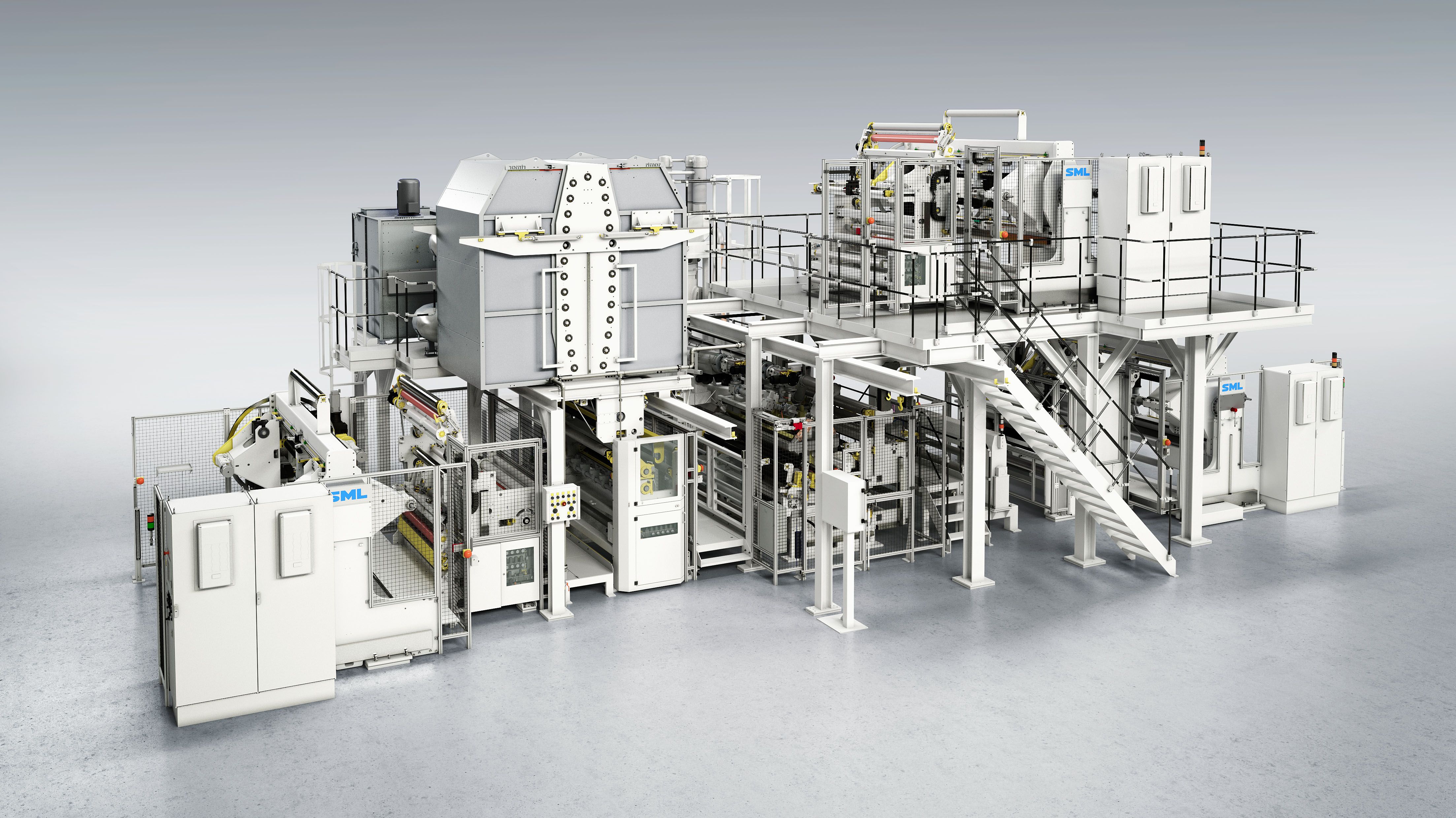

SML wishes to announce the installation of its new and innovative FlexPack pilot line for various extrusion coating and laminating applications. This industrial size lab line is earmarked for comprehensive product sampling, as well as the support of customers during process and product development. Trials under absolutely real production conditions are thus entirely possible.

A wealth of applications

The applications of the latest FlexPack line are as diverse as the needs of our customers. The pilot line has been specially designed for the extensive range of structures used in the flexible packaging industry. Apart from these applications, the lab line is also suitable for the extremely efficient production of highly innovative breathable products, as it is equipped with SML’s DoubleCoat process (patent pending). Coated and laminated products from an SML FlexPack line are employed in the following market segments:

- Barrier packaging

- Liquid packaging

- Industrial packaging

- Paper coatings

- Monolithic, breathable textile coatings (TPU, TPE) for roofing, hygiene and medical applications using the DoubleCoat process

- Vapour barriers and reinforced products for the construction industry

High-quality components are used throughout the FlexPack pilot line, which can handle substrate widths of 800 to 1,650mm. User-friendly operation is guaranteed at production speeds of up to 450 m/min and key components in the line include fully automatic shaftless turret unwinders, a primer station with a closed chamber doctor blade system, ozone treatment for the melt curtain and a shaftless winder at the end of the production process.

Pilot plant ready for customer trials

The new state-of-the-art FlexPack pilot plant has been installed at SML headquarters in Lenzing, Austria and will be available for first-hand inspection and customer trials from May 2016 onwards