- Spinning lines

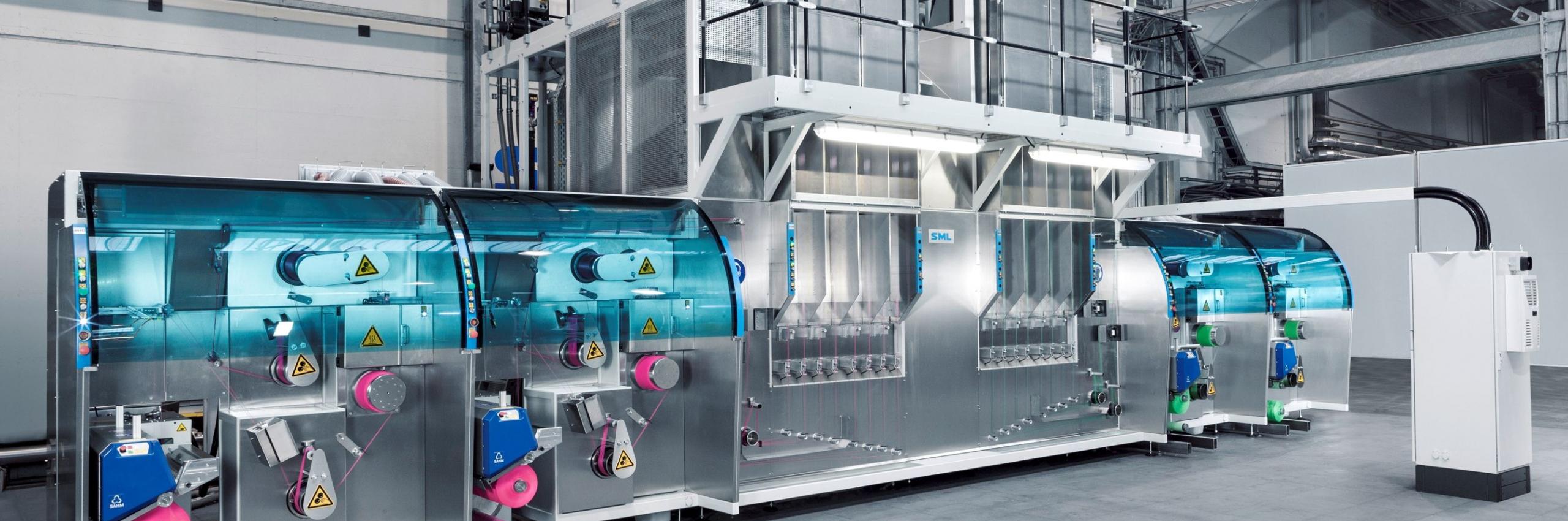

- Austrofil BCF spinning lines

Austrofil BCF spinning lines

The byword for top quality

multifilament BCF spinning lines.

The greatest need for bulk continuous filament yarns comes from the carpet industry and a number of other niche markets, such as door and window seals. The outstanding quality of the yarns created with our high-tech spinning machines has led to us receiving a huge positive response from the market in this area. The multifilmant yarns provide impressive results in terms of tenacity, elongation, and rest shrinkage. A special feature for the carpet making process is the uniquely high crimp that can be achieved with our machines, making it possible to reduce material usage by as much as 20%. The bottom line: an investment in an SML spinning line is an investment that pays off quickly!

Line Types

The top choice for small batch sizes.

SML BCF PP monocolour compact

multifilament spinning line

This BCF line is the most efficient and cost-effective entry-level model in the world of BCF technology. Its compact design demands little floor space and is particularly suitable for small production batches.

| BCF PP 2x2C / 75 Compact, 4 ends, monocolour | |

|---|---|

| Polymer | Polypropylene, MFR 18 - 27 |

| Titer range | 1,000 - 5,000 dtex |

| Output capacity | 160 kg/h, 3.8 t/d |

Parallel production possibilities.

The SML BCF PP monocolour twin

multifilament spinning line

This BCF line is equipped with two extruders and two separate spinning heads. This makes it possible to either manufacture one product or simultaneously produce two completely different batches in a titre range of 1,200 to 5,000 dtex, combining the benefits of having two small spinning machines with those of having one large machine. And making your production even more flexible in the process. The line’s maximum output rate also clocks in at an impressive 320 kg/h.

| BCF PP 4x2 / 2x75 TWIN, 8 ends, monocolour | |

|---|---|

| Polymer | Polypropylene, MFR 18 - 27 |

| Titer range | 1,200 - 5,000 dtex |

| Output capacity | 320 kg/h, 7.6 t/d |

Expanding the range of possibilities.

The SML BCF PP tricolour

multifilament spinning lines

This spinning line is specifically designed for the carpet industry and offers a limitless range of colour combinations and shades, following actual design trends expanding your options in carpet design. Its performance is no less remarkable, supporting two different processing modes: mode 1, for one large tricolour or monocolour batch with 12 ends and an output of 480 kg/h; and mode 2, for the simultaneous production of three different monocolour batches with 4 ends and an output of 160 kg/h each.

| BCF PP 4x2 T / 3x75, 8 ends, tricolour | |

|---|---|

| Polymer | Polypropylene MFR 18 - 27 |

| Titer range | 1,000 - 5,000 dtex |

| Output capacity | 320 kg/h, 7.6 t/d |

| BCF PP 6x2 T / 3x75, 12 ends, tricolour | |

|---|---|

| Polymer | Polypropylene MFR 18 - 27 |

| Titer range | 1,000 - 5,000 dtex |

| Output capacity - Mode 1: 1 large tricolour or monocolour batch with 12 ends | 480 kg/h |

| Output capacity - Mode 2: 3 different monocolour batches with 4 ends | 3 x 160 kg/h |

Benefits that broaden your potential

- Low line height

- Production of unique multifilament yarns to set new trends and suit the latest style developments

- SML pre-intermingling technology supports the production of differently coloured-separated tricolour yarns

- High filament counts with ideal cooling conditions

- Top-grade colour constancy, meaning colours can always be reproduced