- Winding technology

- SML winding technology

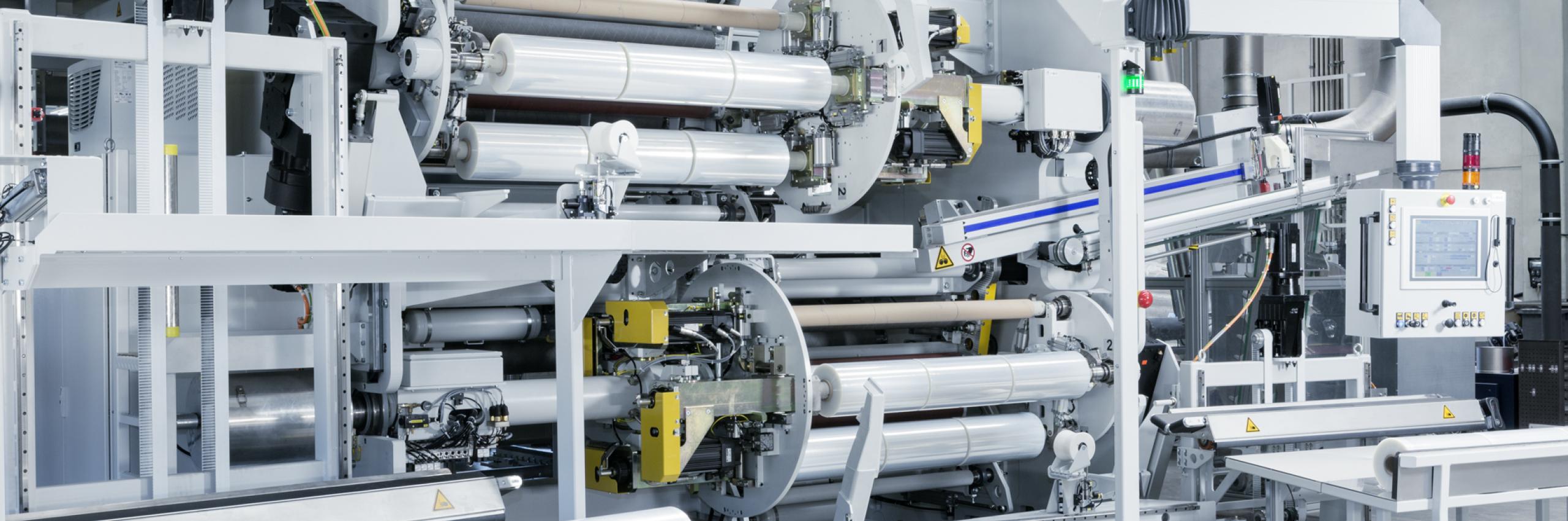

SML winding technology

Precise, efficient, exhaustively customised.

Our wide selection of winders is proof that we are more than simply extrusion specialists.

SML offers a variety of winder systems to suit different customer preferences and applications. Each of our winder solutions is customised for the entirety of the process at hand, giving you the edge you expect from us - excellent winder quality at an attractive price point.

Further improvements included.

Our engineers always perfectly tailor the winders to the process at hand, further developing the technology in incremental steps. After all, our customers want fast and efficient end-to-end solutions that work perfectly at all locations and at all times.

At SML, we do everything we can to make that happen. We use one of the most precise winding technologies around to ensure optimum roll quality in your production. And for good reason: That allows our customers to unlock the full potential of our production lines, while relying on a single point of contact for the entire investment project.

Another way to boost efficiency!

Winder Types

SML winders for stretch wrap film

Film that winds up perfect!

It is the constant edge in winding technology, that helps making SML the global technology leader for stretch film lines. We consider our peak performance winders as decisive in terms of overall line performance. SML offers three types of winders for stretch film lines - all of them with a solid, vibration-free steel-frame construction and perfectly designed to resist the dynamic forces generated at high production speeds.

| Winder | W3000-4S | W4000-2S | W4000-4S |

|---|---|---|---|

| Thickness range | 8 - 35 μm | 8 - 50 μm | 8 - 50 μm |

| Max. mechanical speed | 650 m/min | 850 m/min | 850 m/min |

| Winding width | 4 - 6 x 500 mm | 3 - 12 x 500 mm | 3 - 12 x 500 mm |

| Part roll width | 400, 450, 500 mm | variable | variable |

| Winding on 2-inch cores | yes | no | yes |

| Winding on 3-inch cores | yes | yes | yes |

| Coreless winding | no | yes | yes |

| Max. mechanical diameter 2-inch | 180 mm | no | 180 mm |

| Max. mechanical diameter 3-inch | 400 mm | 425 mm | 425 mm |

| No. of winding stations per turret | 4 | 2 | 4 |

| No. of winding turrets | single | single / double / triple | single / double / triple |

| No. of winding shafts | shaftless | 2 / 4 / 6 | 4 / 8 / 12 |

| Minimum cycle time | 20 s | 60 s | 20 s |

|---|---|---|---|

| Film tail | very short | standard | ultra short |

| Core and roll handling manual | no | optional | no |

|---|---|---|---|

| Core and roll handling automatic | yes | yes | yes |

SML winders for CPP/CPE/CAST-PET/barrier film

The secret to achieve precision.

SML is focusing on tiniest details to make great things happen. Both our extra large mother roll winders with up to 6.2 m width as well as our inline slitting winders are the result of intensive R&D work - and our constant strive for precision in any detail. SML’s winders offer worldwide unmet roll quality from small to very large diameters, accurate tension control and gap or contact winding for defined roll hardness.

| Winder | W1300 | W1500 | W2000 | W6000 |

|---|---|---|---|---|

| Film thickness range | 15 - 300 µm | 12 - 300 µm | 15 - 300 µm | 15 - 120 µm |

| Max. mech. speed | 450 m/min | 350 m/min | 400 m/min | 400 m/min |

| Max. winding width | 3,900 mm | 1,950 mm | 3,150 mm | 6,700 mm |

| Winding shaft/ pipe diameter | 6 / 8 / 10 inch | 6 inch | 3 or 6 inch | 10 inch / 450 mm |

|---|---|---|---|---|

| Max. mech. diameter | 1,500 mm | 1,200 mm | 980 mm | 1,300 mm |

| W2000 XL: 1,300 mm | ||||

| Winding direction | top outside | top inside or outside | top inside | top outside |

*Depending on end film width and product

| Roll handling | manual | manual | automatic | manual |

|---|---|---|---|---|

| Oscillation | frame | frame | winder or frame | frame |

SML winders for hygiene backsheet

High-performance winders for higher productivity.

Boosting productivity while extending the world’s highest quality standards are one of SML’s key activities in the field of hygiene film. We are offering a wide range of peak performance winders for hygiene film lines - from mother rolls for printing to inline slitting winders for finished products. Based on intensive R&D works, all of our winders for hygiene films lines are constantly upgraded with new features.

| Winder | W1300 | W1500 | W2000 aerofilm |

|---|---|---|---|

| Film weight range | 15 - 70 g/sqm | 15 - 70 g/sqm | 10 - 70 g/sqm |

| Max. mechanical speed | 450 m/min | 350 m/min | 500 m/min |

| Max. winding width | 3,900 mm | 1,950 mm | 2,800 mm |

| Winding on 3-inch cores | no | optional | yes |

|---|---|---|---|

| Winding on 6-inch cores | yes | yes | yes |

| Max. mechanical diameter | 1,500 mm | 1,200 mm | 1,300 mm |

| Winding direction | top outside | top outside or inside | top inside |

| Roll handling | manual | manual | automatic |

|---|---|---|---|

| Oscillation | frame | frame | frame or winder |

SML winders for PET/R-PET sheet

The right winder for the perfect product every time.

From semi-automatic turret winders, A-frame trolley winders or cantilever winders to fully automatic high-tech winders without the need of a film accumulator: We at SML have collected decades of inhouse-specialist knowledge in the field of PET / R-PET sheet winding technology. This allows us to offer outstanding winding quality, setting the global benchmarks in precision.

| Winder | W500 | W600 | W550 | W900 | W2000 XL |

|---|---|---|---|---|---|

| Line width | 1,050 - 2,200 mm | 1,050 - 1,800 mm | 1,050 - 1,800 (2,200) mm | 1,050 - 2,200 mm | 1,650 - 2,200 mm |

| Number of webs | up to 4 | up to 4 | up to 4 | up to 4 | up to 4 |

| Core ID (inch) | 3, 6, 8 | 3, 6, 8 | 3, 6, 8 | 3, 6, 8 | 3,6 |

| Thickness range | 150 - 1,800 µm | 150 - 1,800 µm | 150 - 1,800 µm | 150 - 1,200 µm | 150 - 1,800 µm |

| Max. mech. speed | 70 m/min | 70 m/min | 70 m/min | 70 m/min | 100 m/min |

| Accumulator | yes | yes | yes | yes | no / yes |

| Max. roll diameter up to* | 1,200 / 2,000 mm | 1,200 / 1,400 mm | 1,200 mm | 1,200 mm | 1,200 mm |

*Depending on end film width and product

SML winders for PP/PS/barrier thermoforming sheet

High-tech for excellent production reliability.

SML offers a wide choice of winders for PP/PS thermoforming sheet lines - including semi-automatic turret winders, cantilever winders and A-frame trolley winders. The most important things they have in common: highest technical standards, precision and excellent production liability - based on SML’s decade-long specialist knowledge in the field of winding technology, our constant R&D activities and the strive of our engineers to offer equipment at the highest quality level.

| Winder | W500 | W600 | W550 |

|---|---|---|---|

| Net film width up to | 2,100 mm | 1,550 mm | 1,550 mm |

| Number of webs | up to 6 | up to 3 | up to 3 |

| Core ID (inch) | 3, 6, 8 | 3, 6, 8 | 3, 6, 8 |

| Thickness range | 250 - 2,500 µm | 250 - 2,500 µm | 250 - 2,500 µm |

| Max. mechanical speed | 70 m/min | 70 m/min | 70 m/min |

| Accumulator | yes | yes | yes |

| Max. roll diameter up to* | 2,000mm | 1,000 mm | 1,200 mm |

*Depending on shaft diameter, roll width and number of webs

SML winders for coating and laminating lines

Peak performance winders for many different applications.

SML’s continuous investments in the development of winding technology for coating lines is paying off - in terms of performance at high productions speeds, in terms of liability and in terms of global technology leadership. Today, SML offers a large variety of peak performance winders for all relevant extrusion coating applications: from winders for light-weight laminates to heavy textiles and cardboards, shaftless winders for convenient roll handling and product specific cross-cutting units.

| WINDER | W1500 WS / SL | W1800 | W2000 |

|---|---|---|---|

| Max. mechanical speed | 450 m/min | 600 m/min | 600 m/min |

| Max. winding width | 2,400 mm | 4,800 mm | 2,900 mm |

| Inline slitting | No | Yes | Yes |

| Max. mechanical diameter | 1,270 mm | 2,000 mm | 980 or 1,500 mm |

| Max. roll weight | 2,000 kg | 4,000 kg | 2,500 kg |

| Winding direction | both | top inside | top inside |

| Winding tension | 50 - 750 N | 50 - 3,500 N | 30 - 300 N |

| Contact roll pressure | 100 - 1,800 N | 50 - 3,500 N | 50 - 500 N |

| Roll handling | manual | automatic | fully automatic |

SML unwinders for coating and laminating lines

Unwinders for every type of substrate.

SML demonstrates its technical excellence and innovative strength one more time in the large field of unwinding systems for coating lines. We at SML are offering unwinders for every type of substrate and for a variety of applications - from simple double station systems with a manual splicing unit to fully automated turret unwinds for splicing at full production speed. Among our innovative features: options like bi-directional unwinding, ultra-thin alu-unwinding and different edge guiding and roll positioning systems.

| UNWINDER TYPE | double unwinder | unwinder UW1500 WS / SL | unwinder UW1500 SL-H |

|---|---|---|---|

| Max. mechanical speed | 150 m/min | 450 m/min | 600 m/min |

| Max. substrate width | 5,200 mm | 2,400 mm | 4,500 mm |

| Max. mechanical diameter | 1,500 mm | 1,270 mm | 1,600 mm |

| Core clamping | shafted / shaftless | shafted / shaftless | shaftless |

| Max. roll weight | 4,500 kg | 2,000 kg | 4,000 kg |

| Unwinding direction | both | both | both |

| Roll handling | crane | crane / forklift / lifting table | lifting table / lifting table |