Breadcrumb

PET sheet extrusion: SML launches applicator unit for anti-block liquid

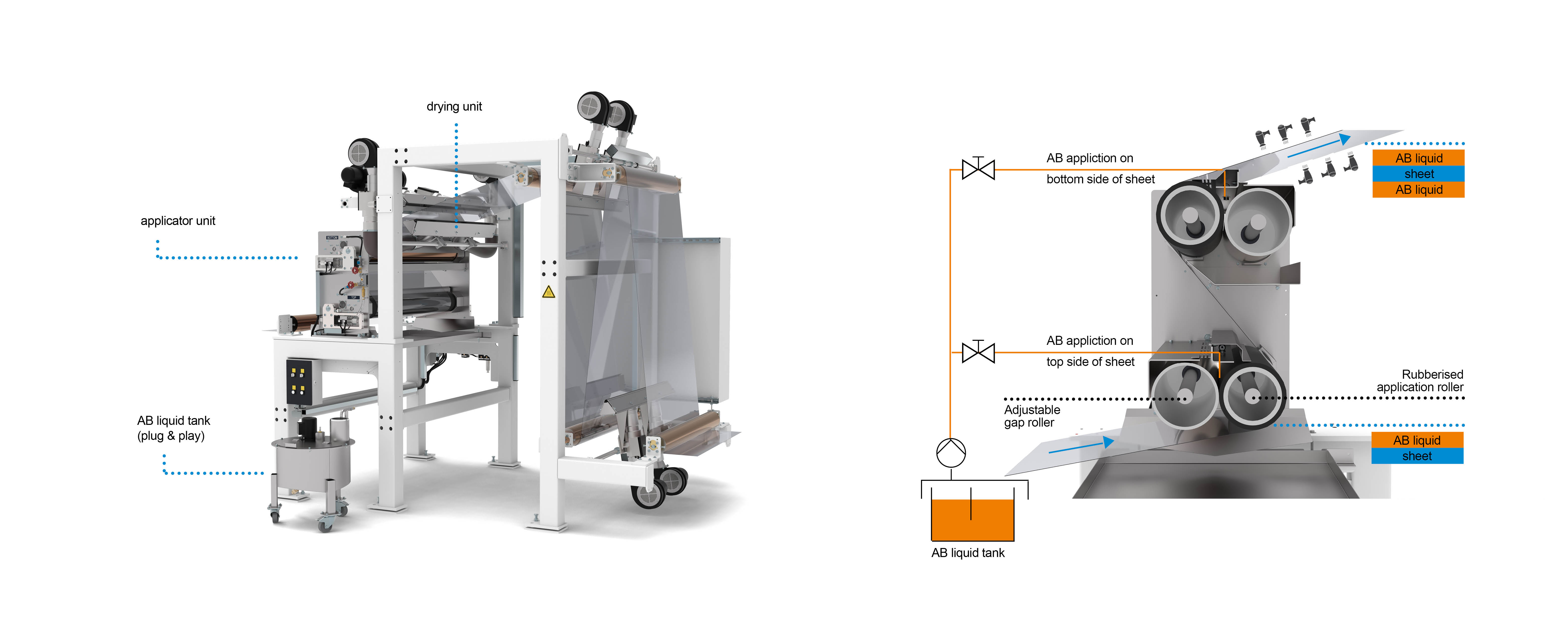

For its sheet lines for thermoforming applications, SML now offers a flexible, easy-to-operate and retrofittable applicator unit for the external application of AB liquid. It consists of pairing an aluminum gap roller and a rubberized application roller, by means of which the anti-block emulsion is applied to the sheet. The liquid is dosed to the roller gap from a movable tank container which is fitted with a pump used to convey and constantly mix the emulsion.

The quantity applied is easily adjusted via a simple-to-use regulating valve. The movable tank container gives SML’s applicator unit a high level of flexibility since it can be easily uncoupled. In interaction with a second prepared container, it allows very fast, “flying” product and recipe changes. Depending on the requirements of production, the AB liquid can of course be applied on one or on both sides of the sheet. Additionally, anti-block and anti-static agents can be combined in one liquid mixture and applied using SML’s applicator unit in one sole step. Antifog can also be applied. Directly after the applicator unit, the treated sheet is dried with hot air blowers.

For further information on the applicator unit, please contact: Martin Kastner, [email protected]

Redlham, 18.06.2024