Breadcrumb

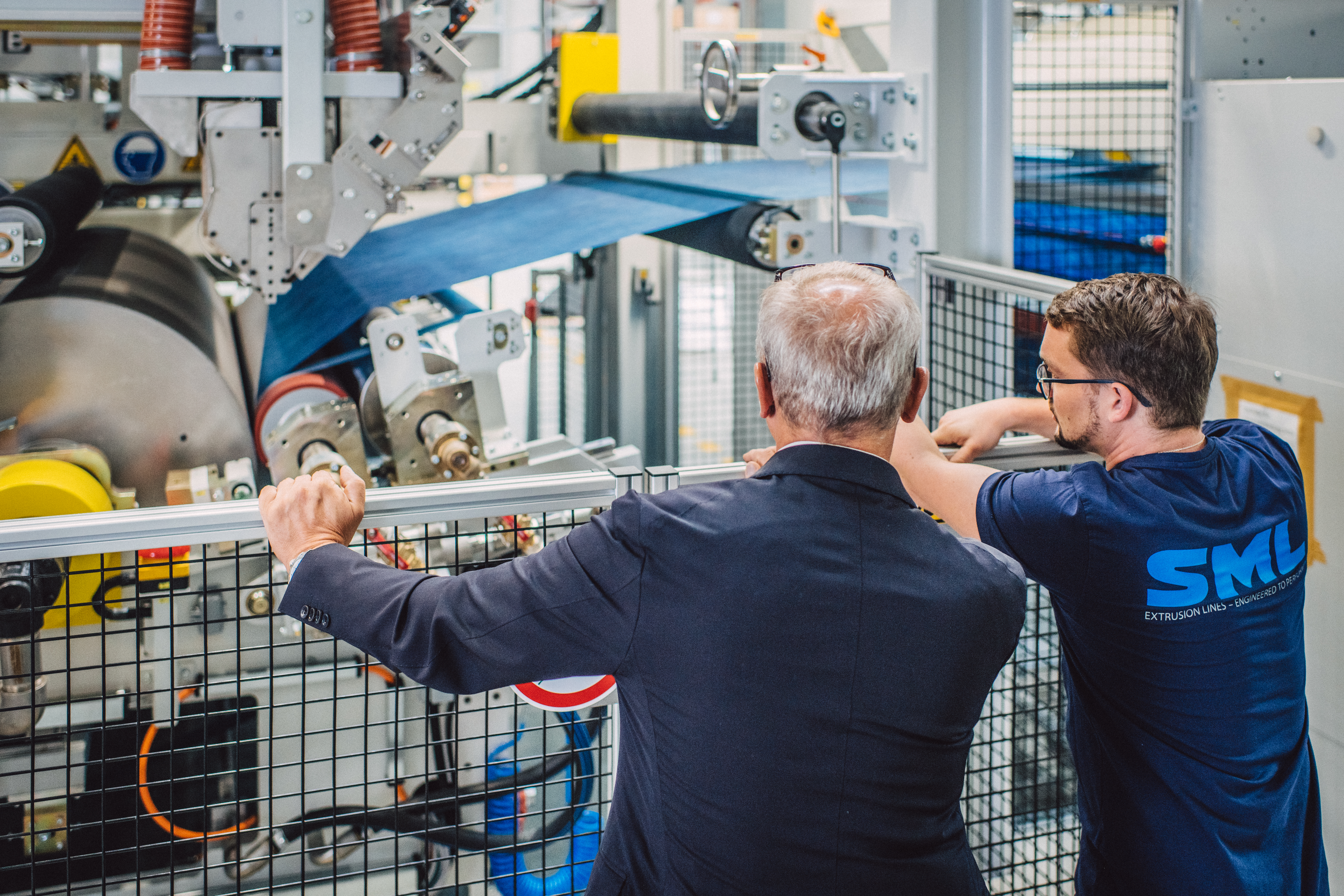

Advanced FlexPack extrusion coating line new at SML's Technology Centre

From 3rd quarter 2023 onwards, a completely new production scale FlexPack® extrusion coating and laminating line will be available in SML’s Technology Centre. The line will be ready for performance tests, sample production and joint R&D projects with customers and partners.

SML’s new state-of-the-art FlexPack® line comes in a new design and features a number of technical innovations: The plant is equipped with three extruders, that are configured to process a huge variety of different polymers – ranging from polyolefins to TPU, TPE, PET, PLA and EVOH.

To increase the output range for certain materials, the main extruder’s drive power had been raised to reach screw speeds up to 425 rpm. A Smart Drain unit supports fast and efficient polymer change overs. Melt homogeneity can be observed via an Infrared Line Scanner, that constantly measures the temperature profile in the melt curtain.

The co-extrusion feedblock provides up to five layers, which enables the production of barrier-coated film for flexible packaging. Apart from two automatic unwinds, the new line is equipped with an additional single unwind for the production of reinforced laminates. Fitted with the patented DoubleCoat technology, the new plant also offers the functionality to create ultra-thin breathable membranes.

“Manufacturers of laminates, membranes and composites frequently use the demonstration lines in our Technology Centre and benefit from our understanding of process technology, when it comes to the creation of new products or the optimisation of production processes”, Johannes Danter, Product Manager at SML, states.

Redlham, 29.06.2023