Breadcrumb

SML offers production line for hygiene protective materials

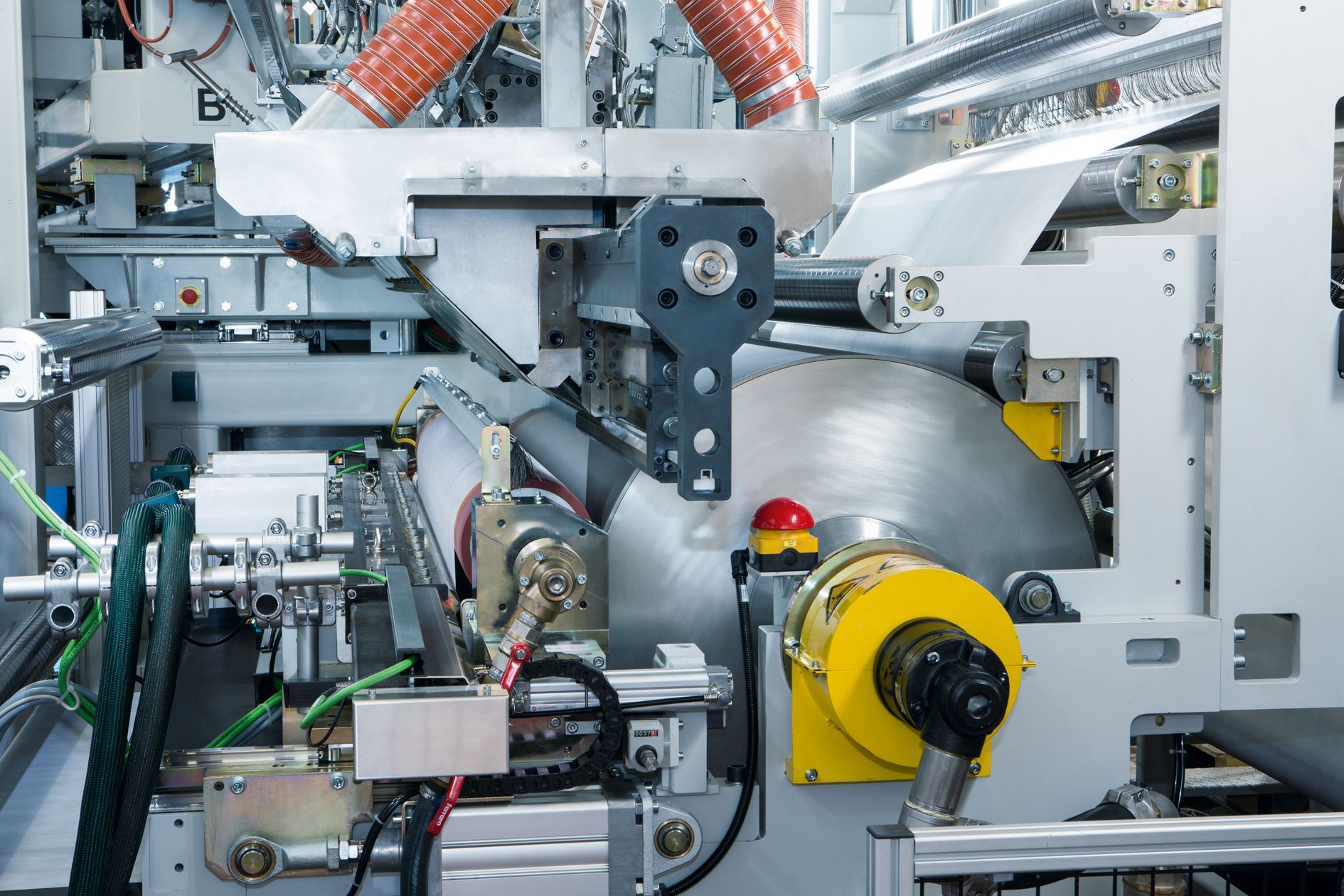

Hygiene protective clothing is in high demand in these difficult times and worldwide production capacities are limited. SML has available a completely equipped production-size FlexPack line including its patented DoubleCoat process at its Austrian headquarters. The line is perfectly suited to manufacturing materials for hygiene applications like protective clothing and surgical coverings. The line is offered to customer trials; it can also be purchased directly from SML with a very short delivery time.

SML’s FlexPack line manufactures high-tech functional materials with outstanding properties. Laminates in combination with monolithic membranes (such as TPE) provide a highly effective barrier against viruses and bacteria. The material’s breathability and elasticity allow the production of protective clothing with excellent wearing comfort.

- Functional clothing, i.e. breathable protective clothing

- Hygiene applications, i.e. breathable layers in napkins/nappies

- Medical applications, i.e. protective clothes and surgical coverings

Advanced process technology

SML’s DoubleCoat technology integrated into FlexPack extrusion coating lines, combine extrusion coating with hotmelt lamination, which has revolutionised the way in which very thin functional cloths and membranes are produced. On top of this, such lines are perfectly suited to conventional hotmelt lamination of breathable films and nonwovens, as well as extrusion coating and lamination. Absolutely tight and breathable materials can be manufactured on the same production line.

Facts & Figures:

Products: Hygiene and technical applications plus flexible packaging

Product width (FlexPack®1800): 800 – 1,650 mm

Coating weight: 7 – 50 g/sqm (depending on product)

Coating layers: 3-layer

Max. operating speed: 450 m/min (shaftless winding)

Redlham, 29.04.2020