Breadcrumb

Stretch film manufacturer JiaXing Technology: Strong partnerships, quality and efficiency as a basis for success

In 2004, JiaXing Technology commenced the production of stretch wrap film in a rented shop lot factory in Johor, Southern Malaysia. 20 years later, JiaXing now delivers premium film to customers all over Asia. Technically advanced stretch wrap film lines from SML with high output volumes had a share in this success story.

As a manufacturer of stretch film, we strive to improve and cater to each and every demand from our customers. We ensure high quality products at very competitive prices”, Mr. Kent Tan, the CEO and owner of JiaXing Technologies, states.

Today, more than 80 percent of what JiaXing produces is exported overseas. “Our international success was made possible through our dedication to provide premium quality products to our customers. Our machines are equipped with advanced technologies and have a very high output rate”, Mr. Kent Tan explains.

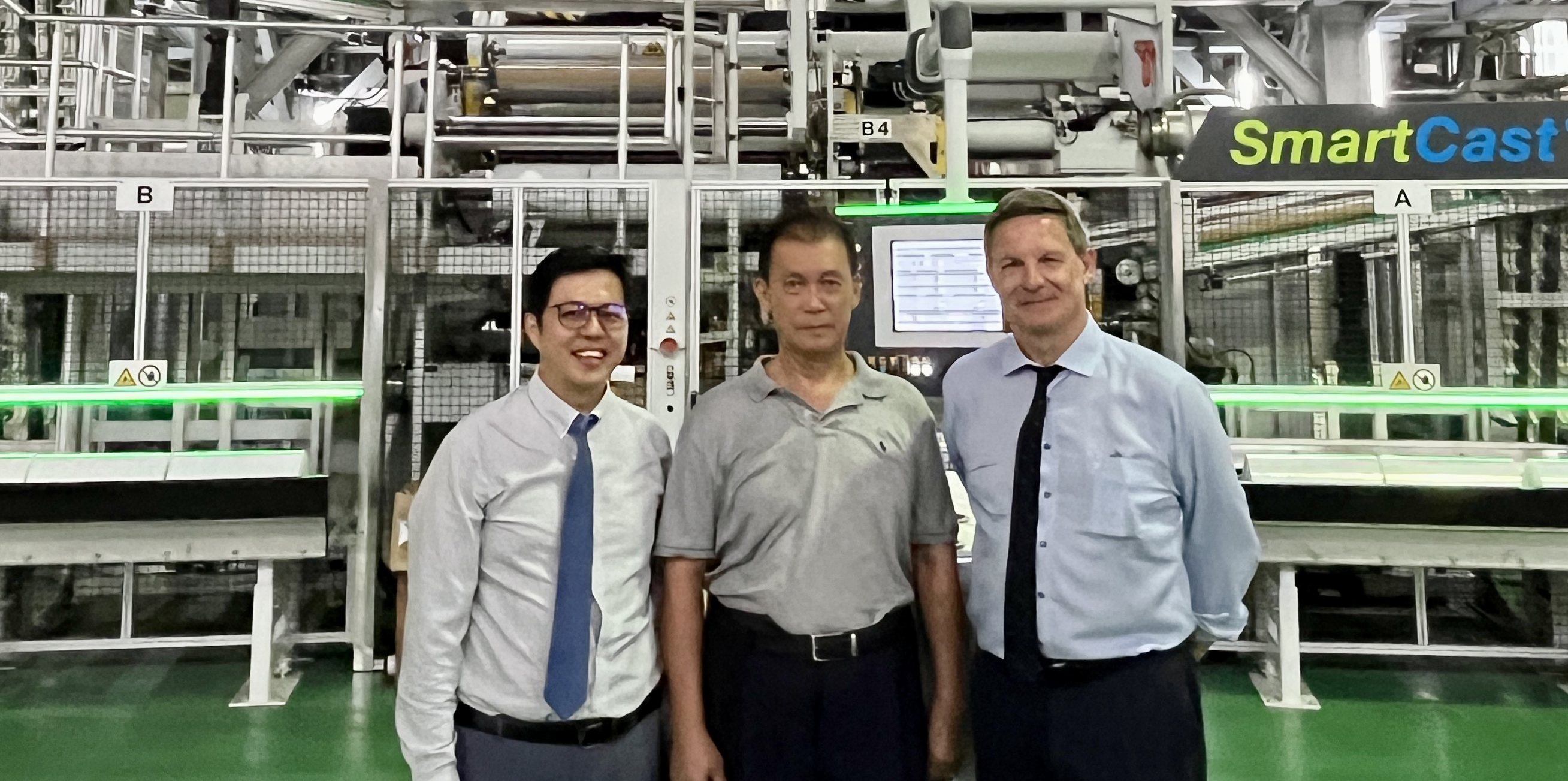

Currently, JiaXing has three stretch wrap film lines from SML in operation: A 2-Meter EcoCompact 4up 3-layer line installed in 2014, a 1.5 Meter MiniCast 3up 5-layer line, commissioned at the end of 2018, and a highly efficient, state of the art 3 Meter Smart Cast 7-layer line that combines high output volumes with maximum flexibility in production since the end of 2022. The investment in extrusion lines from SML goes hand in hand with Jiaxing’s successful business activities.

“Lines from SML are characterised by technical precision, robustness, durability and operational simplicity. In the same way that our systems stand for longevity and reliability, we also always strive for long-term customer relationships”, Dr. Kiat Sen Yap, SML Sales Manager Southeast Asia, explains.

SML has been represented in Asia since 1995, with branch offices in Beijing and Kuala Lumpur. A quickly deployable, highly specialised local service team, including online service providers, drastically reduces line downtimes and waste. It is a priority for SML to offer customers optimum solutions that enable them to achieve their goals.

Key technical characteristics of SML’s stretch wrap film lines such as high output volumes, flexibility, fast product changeovers, low energy consumption and a long service life make a significant contribution towards the overall line efficiency. “Giving manufacturers an edge in their markets, is not only about delivering state-of-the art machinery in terms of product quality and output volume. Above all, investing in machines from SML means competitive advantages through lower production costs and therefore a high return on investment”. Dr. Kiat Sen Yap concludes.

Redlham, 16.05.2024