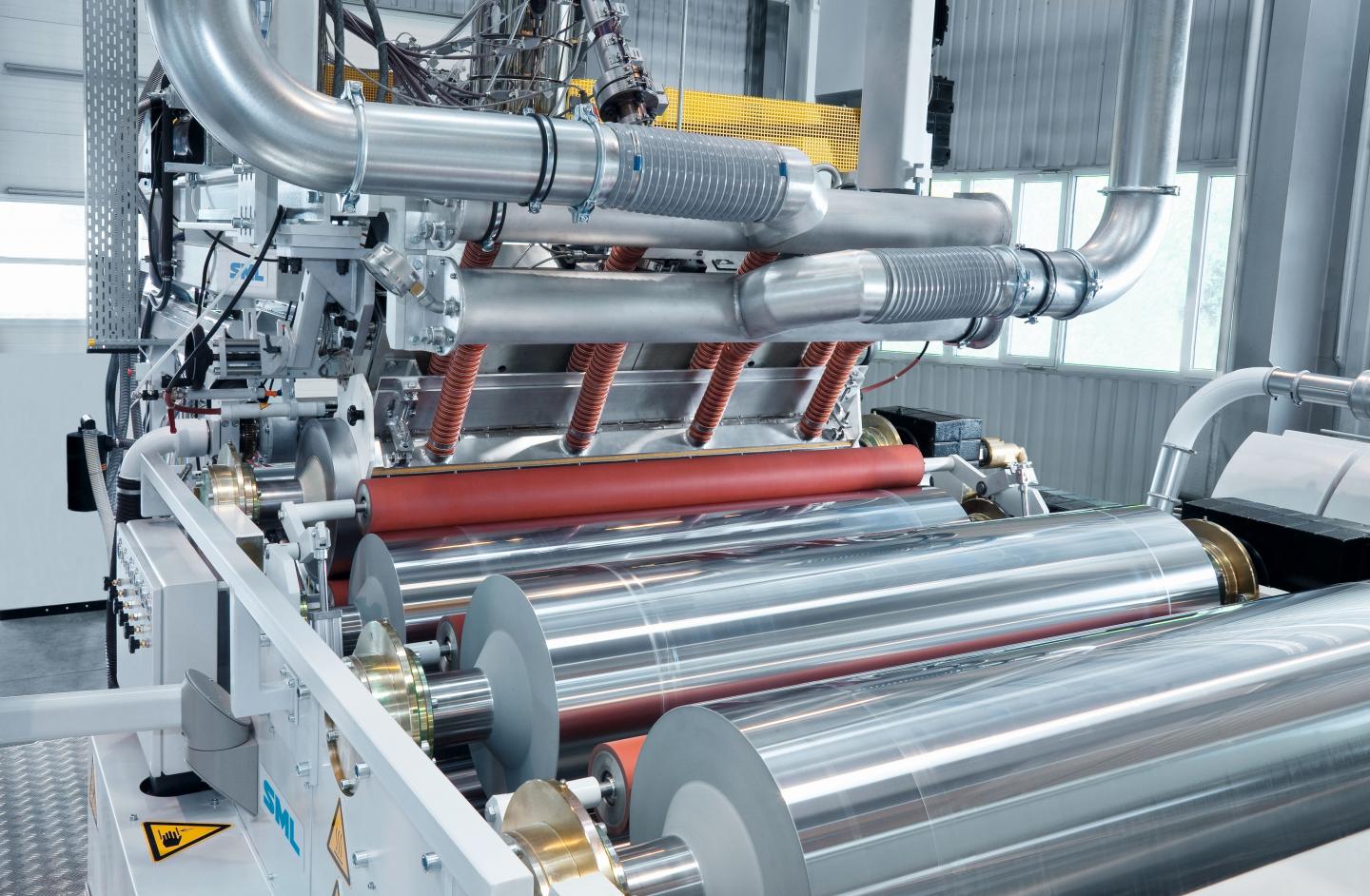

- Cast film lines

- Lines for LiBS film

Lines for LiBS film

Extrusion lines for separator film in

Li-ion batteries.

From consumer electronics to electric bikes and cars to stationary energy storage systems:

Today, powerful and long-lasting Li-ion batteries are a key-driver of technical innovation. One of the most important part of a Li-ion battery is the separator. It is a membrane separating the anode and the cathode inside the battery to prevent short circuits and to allow the free transmission of lithium ions.

We are very proud to be the global market and technology leader in extrusion of high-end separator film for the dry process.

Excellent chemical and thermal stability.

Beside a porosity of more than 40 percent and a uniform pore size, separator film must have excellent properties concerning chemical and thermal stability, tensile strength, low shrinkage and thickness (dimensional strength).

To reach these properties, SML delivers extrusion lines working on a dry process basis. Compared to separators produced in a wet process, the pore structure of separators produced in a dry process is more open and consistent – and therefore these Li-ion battery separator films are better suitable for higher power density.

Eco-friendly – very low consumption of raw materials

Due to the advantages of the dry production technology, SML’s extrusion lines for separator film work very cost efficient and eco-friendly.

Compared with the more complex wet process, it is not necessary to use solvents to excavate the low-molecular material. The separator film leaving SML’s extrusion line can be a one or three layer film on PP or PE-base, in perfect quality for further processing steps.