- Coating lines

- Extrusion coating and laminating lines

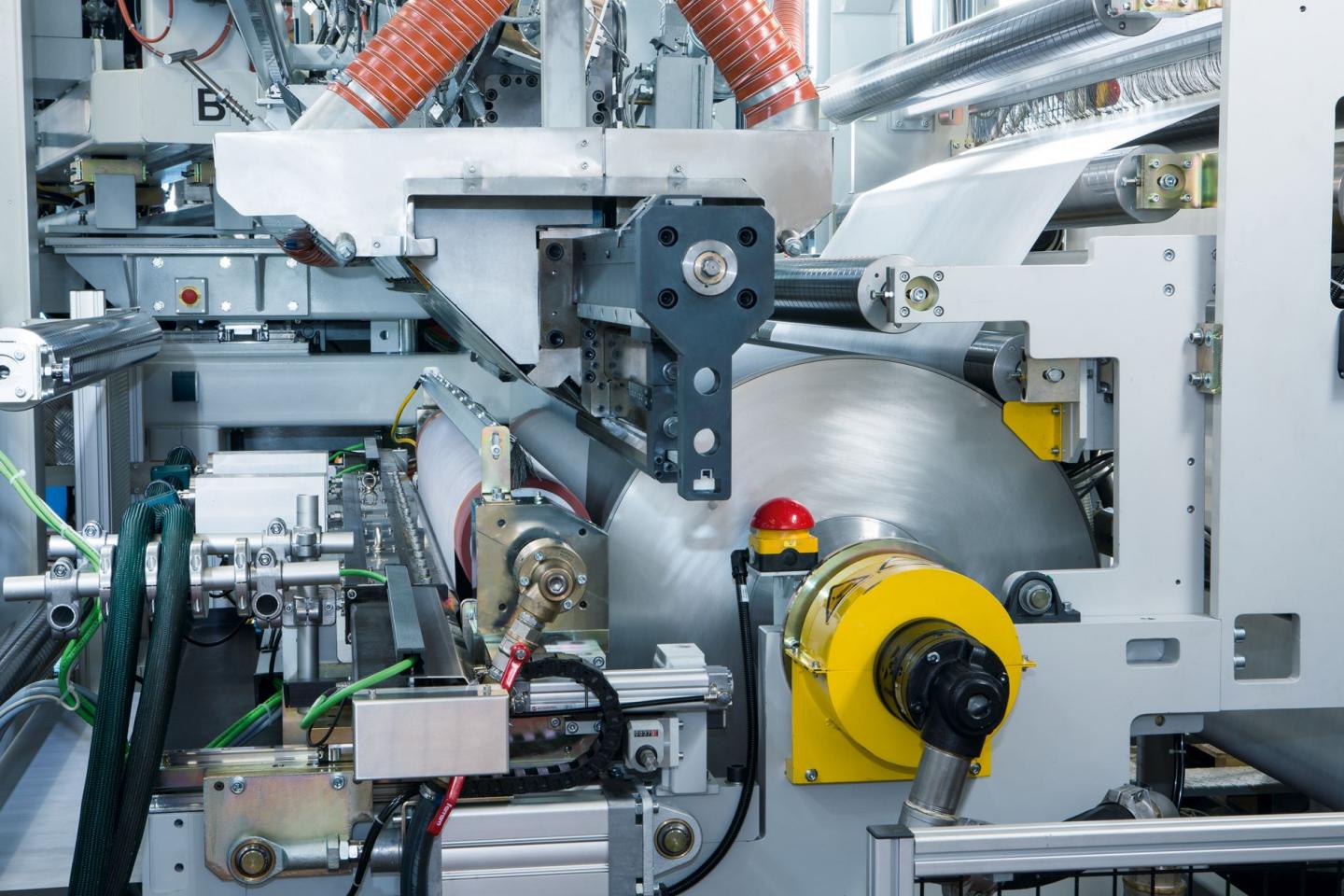

Extrusion coating and laminating lines

Refining complexity into productivity.

SML’s high-performance extrusion coating lines are the right answer, tailored to the hugely diverse requirements that pertain to coating products. Our high-speed extrusion coating and laminating lines set the standard in industries, maintaining flexibility for frequent product changes.

Typical end users include the manufacturers of flexible packaging for the food industry. Manufacturers of breathable films and laminates for hygiene applications, the construction industry and textile makers are others in this category who rely on the extrusion coating process. No matter how your preferences look, SML always has the ideal solution for your final product.

Our systems’ benefits are clear.

- Different winding and unwinding concepts with shafts and shaftless

- High-performance extruders specially tailored to your applications

- Co-extrusion for multi-layer and complex structures

- Optional Tandem or Triplex line design (e.g. for aseptic packaging)

- Components fully integrated in the line control system

- Smile Control System – an intuitive, simple-to-use human-machine interface

Line Types

The benchmark for flexibility in production.

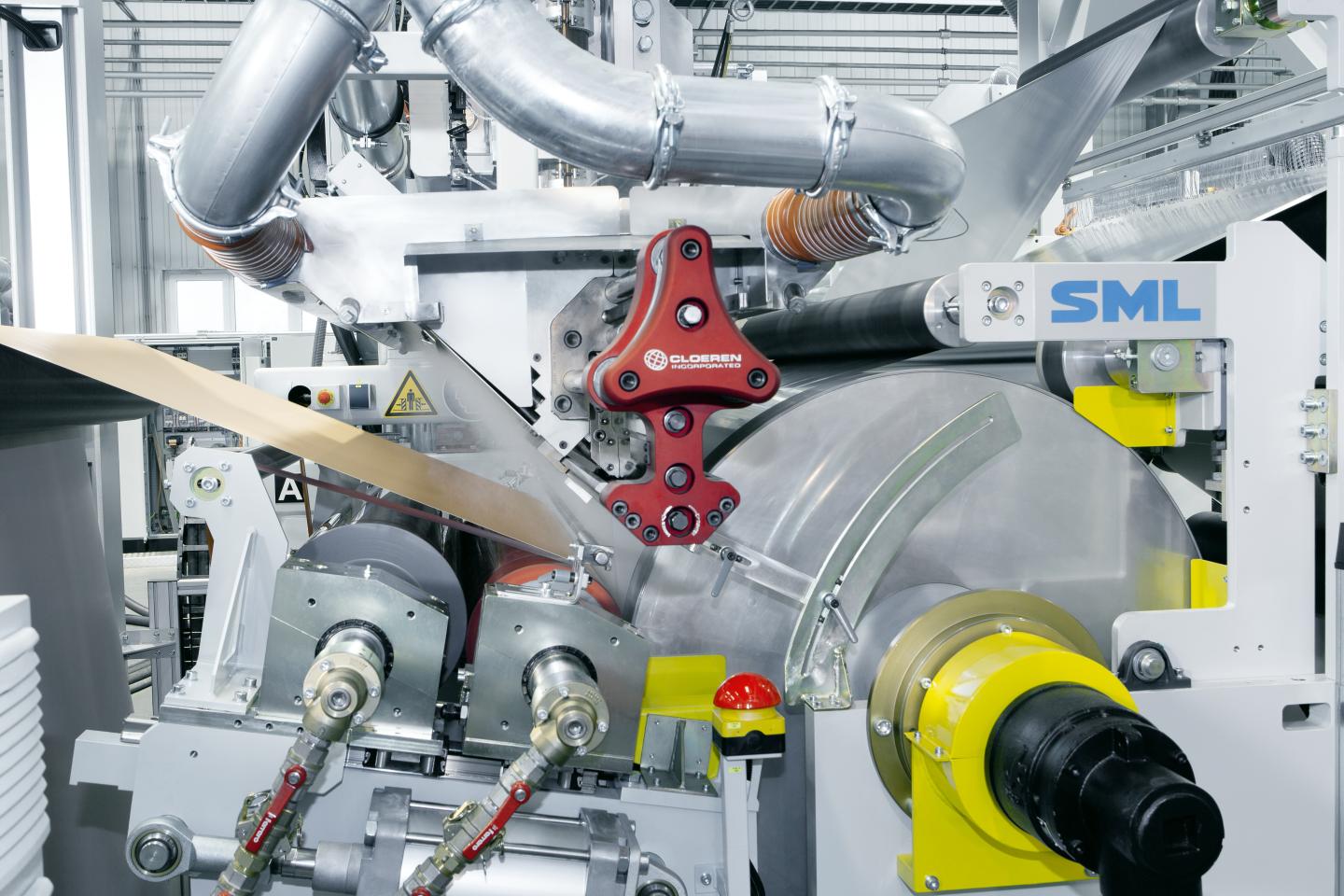

The SML FlexPack

FlexPack is a well-proven SML concept which raises the bar for flexibility and simplicity in coating and lamination. It has been specifically engineered for the dynamic packaging market, but found its place also for technical applications. All options are on the table for customers thanks to the line’s compact and modular design.

The system guarantees a thoroughly safe, cost-effective and user-friendly production while delivering extraordinary product quality. Its modular design means that the coating and laminating line can be custom-engineered for your specific needs, even making it possible to create highly complex lines with relative ease based on our modular construction system.

| Products | flexible packaging, hygiene and technical applications |

|---|---|

| Product width FlexPack 1500 | 700 - 1,350 mm |

| Product width FlexPack 1800 | 800 - 1,650 mm |

| Coating weight | 4 - 50 g/sqm (depending on the product) |

| Coating layers | 3-layer (optional 5-layer) |

| Maximal operating speed | 350 m/min winding shafts |

| Maximal operating speed - shaftless | 450 m/min |

Simply unbeatable in action.

The SML FlexPack

- Demands minimised floor space

- Modular design for flexible applications

- Allows for quick and simple product changes

- Simple to use and to control

- Best in class for productivity and profitability

New horizons for breathable products.

DoubleCoat

Coating layer thickness reduced to an absolute minimum, very high water columns and sensational values for breathability: It even allows materials combinations which where considered to be incompatible so far.

DoubleCoat is SML’s new patented, sequential coating process for the manufacture of breathable products - i.e. in the field of sanitary articles, for the construction industry or for disposable clothing.

Combine the options and gain the edge.

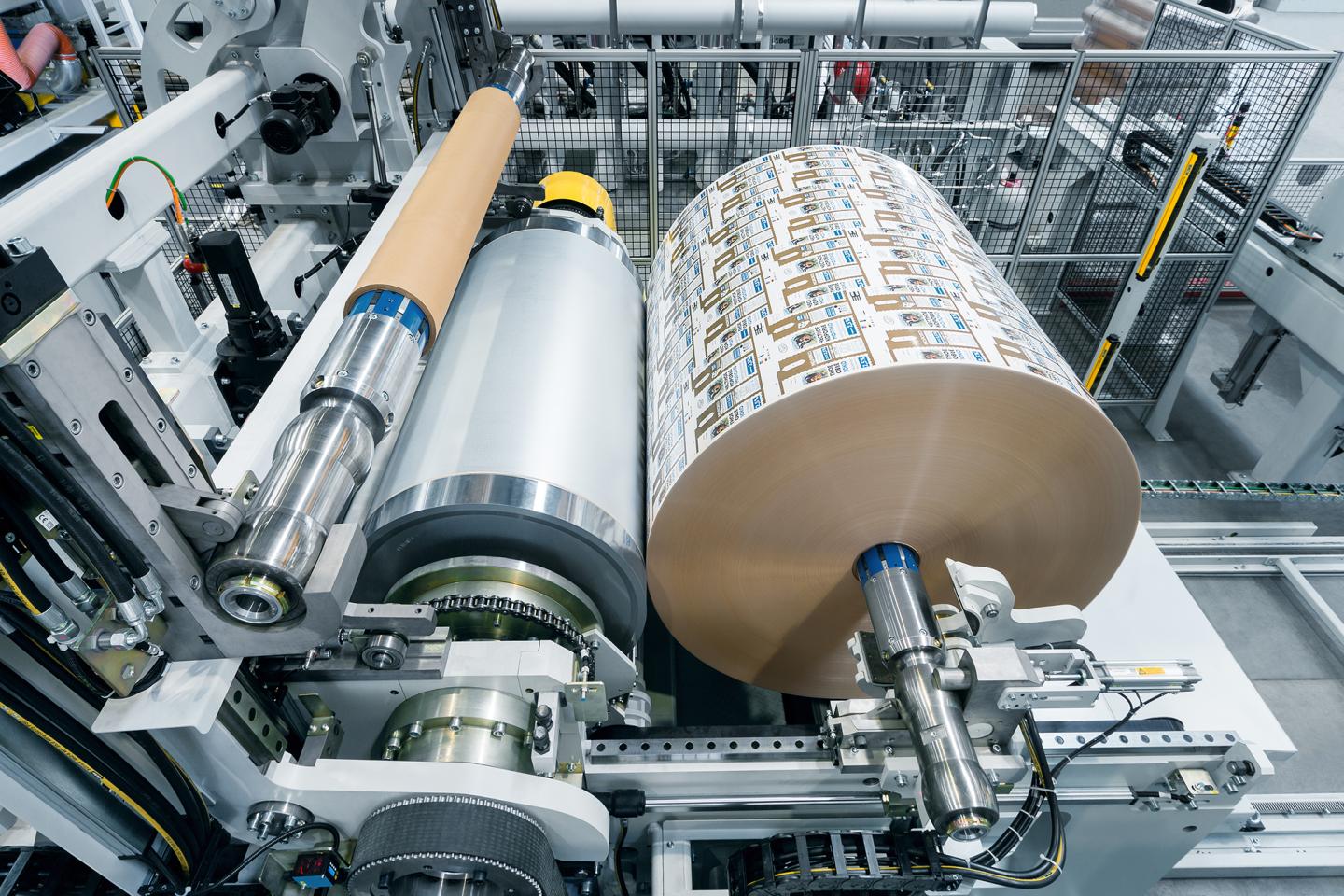

The SML Triplex lines for aseptic packaging

Packaging for beverages extracted from natural food sources such as fruit juice present a particular challenge in the engineering of systems and processes. SML’s coating and laminating lines can be used to manufacture complex composite carton packaging in one simple and cost-effective process.

The centrally controlled 'Smile Control System' plays a key role in this, allowing you to manage the activities simply and conveniently.

| Products | Aseptic board packaging |

|---|---|

| Product width | 700 - 1,650 mm |

| Lamination weight | 15 - 25 g/sqm |

| Inside weight | 20 - 40 g/sqm |

| Decor weight | 12 - 25 g/sqm |

| Total product weight | 150 - 400 g/sqm |

| Maximal operating speed | up to 600 m/min |

Your advantages:

- Production of aseptic board laminates of high quality

- Optimised product change over - low waste

- Durable machine design and comfortable operation

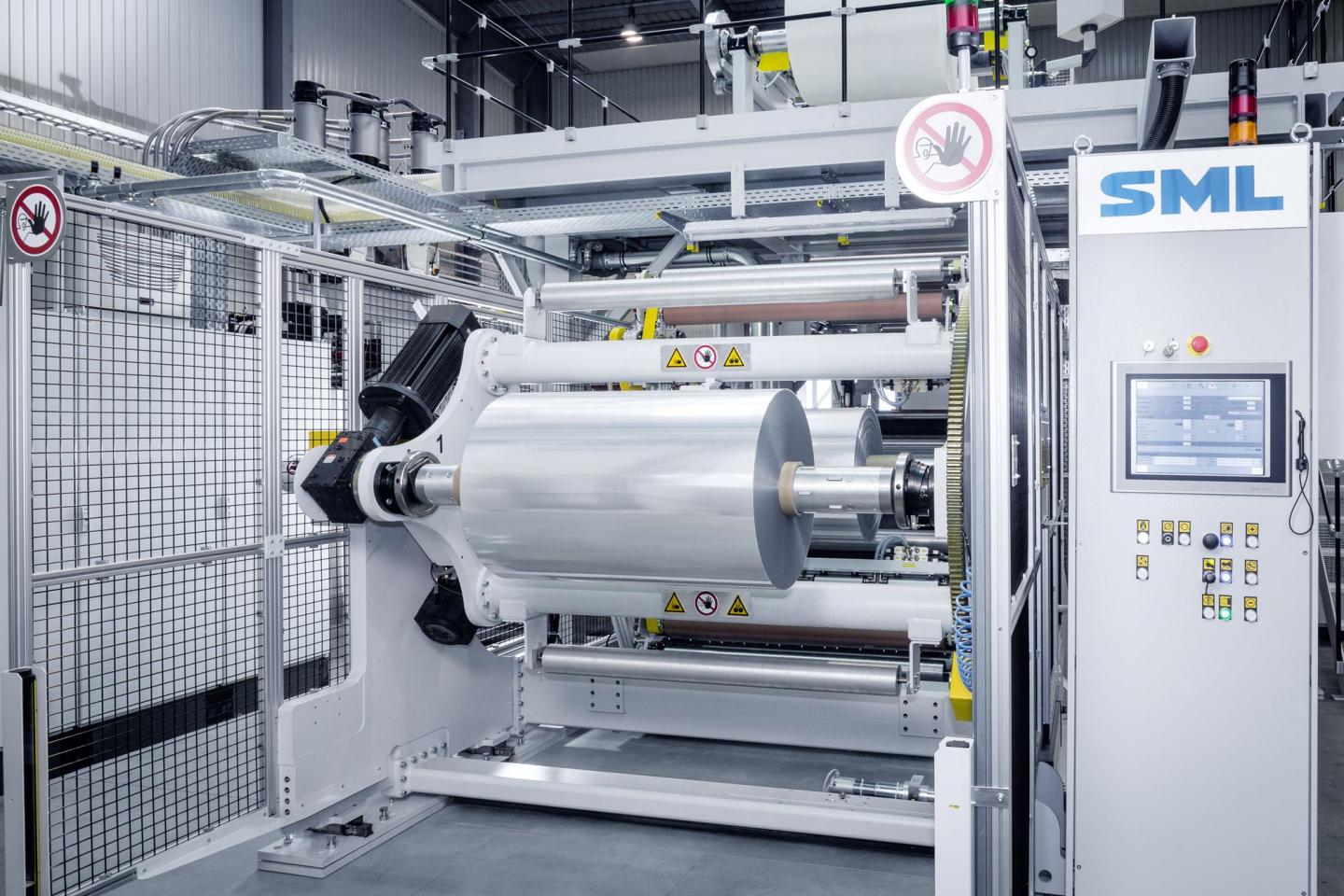

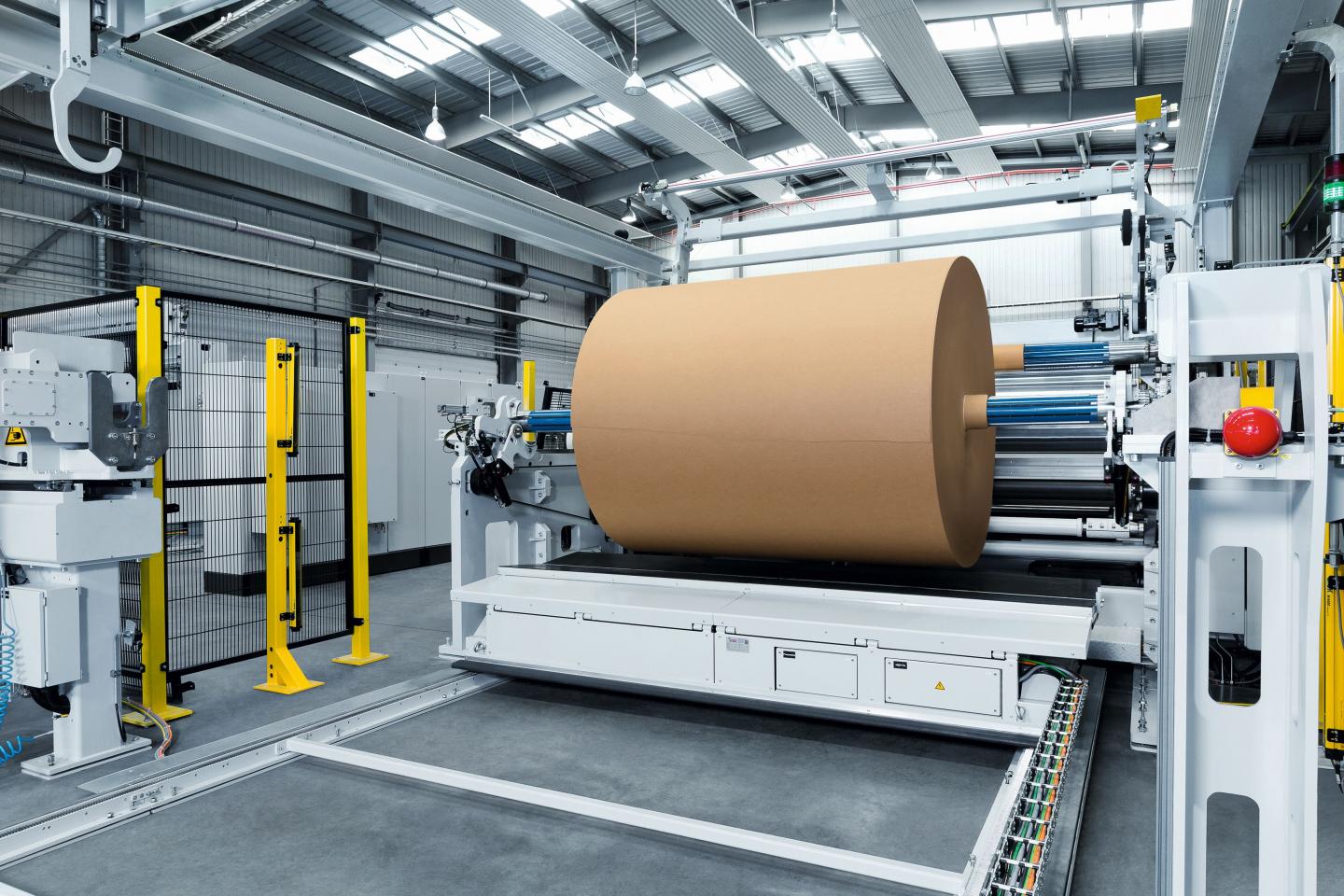

Ready for heavy loads.

SML’s fully automatic drum winder, W1800, is fitted with an automatic reel and shaft handling system and supports the winding of heavy product rolls of up to 4 tons.

Custom solutions to maximise productivity.

The SML coating and laminating lines for large product widths

We supply tailor-made solutions for extremely wide products up to 5,300 mm largely used for technical purposes, always with focus on our customers requirements.

After all, that is the only way to lay the foundation for efficient and economical production in these scenarios.

| Substrates | woven fabric, paper, nonwovens, grids etc. |

|---|---|

| Products | tarpaulins, steel wrap, roofing membranes, carpets etc. |

| Product width | up to 5,300 mm |

| Coating weight | 15 - 80 g/sqm or 80 - 600 g/sqm |

| Extrusion layers | mono or co-extrusion |

| Maximal operating speed | 250 m/min |

Thanks to the custom solutions we have already crafted on many occasions, we are respected as an expert partner in the field that can provide the ideal, reliable machinery to give our customers the edge in production. We would be delighted to take on your challenge in this area, as well – do not hesitate to get in touch!