Breadcrumb

FlexPack® coating line turns complexity into productivity

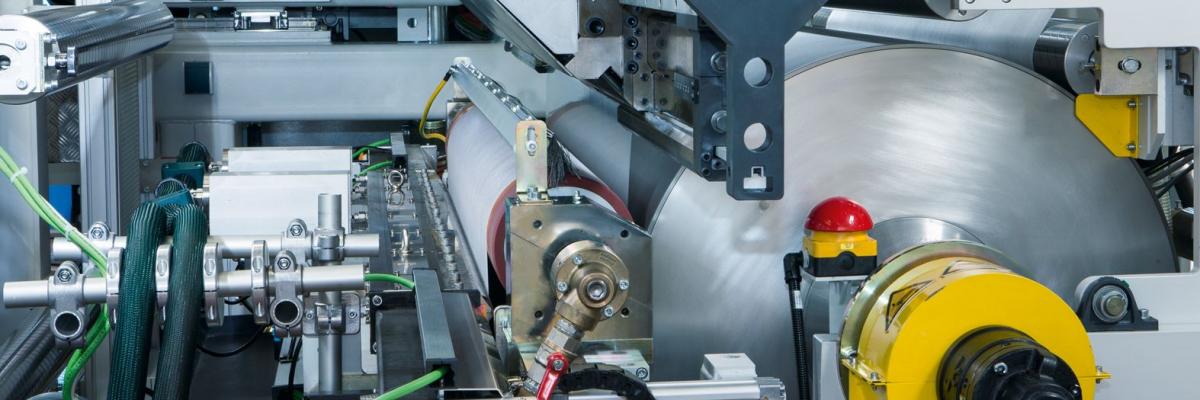

Flexible products constitute one of the fastest growing segments in the packaging industry and SML’s commitment to this high-potential area is reflected by its innovative and skilfully engineered FlexPack® co-extrusion coating and laminating line: From the extruder, the unwinder and laminator to the winders and the system control, SML designs and manufactures everything in-house. The result is technical precision, reliability and easy operability.

Manifold applications possible

With its modular construction, the FlexPack® line can be designed according to specific customer needs and for the extrusion of various raw materials such as PP, LDPE, EVA, EAA, etc. Starting from a basic configuration for simple extrusion coating products, it is possible to equip FlexPack® with additional features that range from a primer coating station, tandem configuration and ozone treatment to supplementary unwinds, etc. This facilitates the manufacture of a variety of commercial packaging materials based on paper, film and aluminium foil substrates including highly complex laminate structures for technical or medical applications. Naturally, maximum flexibility is ensured during product changes, which avoids waste and keeps productivity at the highest possible level.

FlexPack® coating line + DoubleCoat technology = maximum product diversity

In addition, the “DoubleCoat” technology can be integrated into a standard FlexPack® coating line to create further fresh opportunities in the breathable product field. DoubleCoat combines extrusion coating with hot melt lamination and thus enables coating thickness minimisation, as well as product breathability enhancement.

The DoubleCoat and FlexPack® combination is not only suited to the manufacture of soft touch hygiene products such as for femcare articles, but also for technical products that include weather-resistant roofing membranes for the construction industry.

From the second half of 2023, the latest FlexPack® demonstration line will be available for extensive test runs and product sampling at the SML Technology Center.

SML at the ICE Europe 2023: Hall 6, Stand No. 740

Redlham, 07.02.2023