Breadcrumb

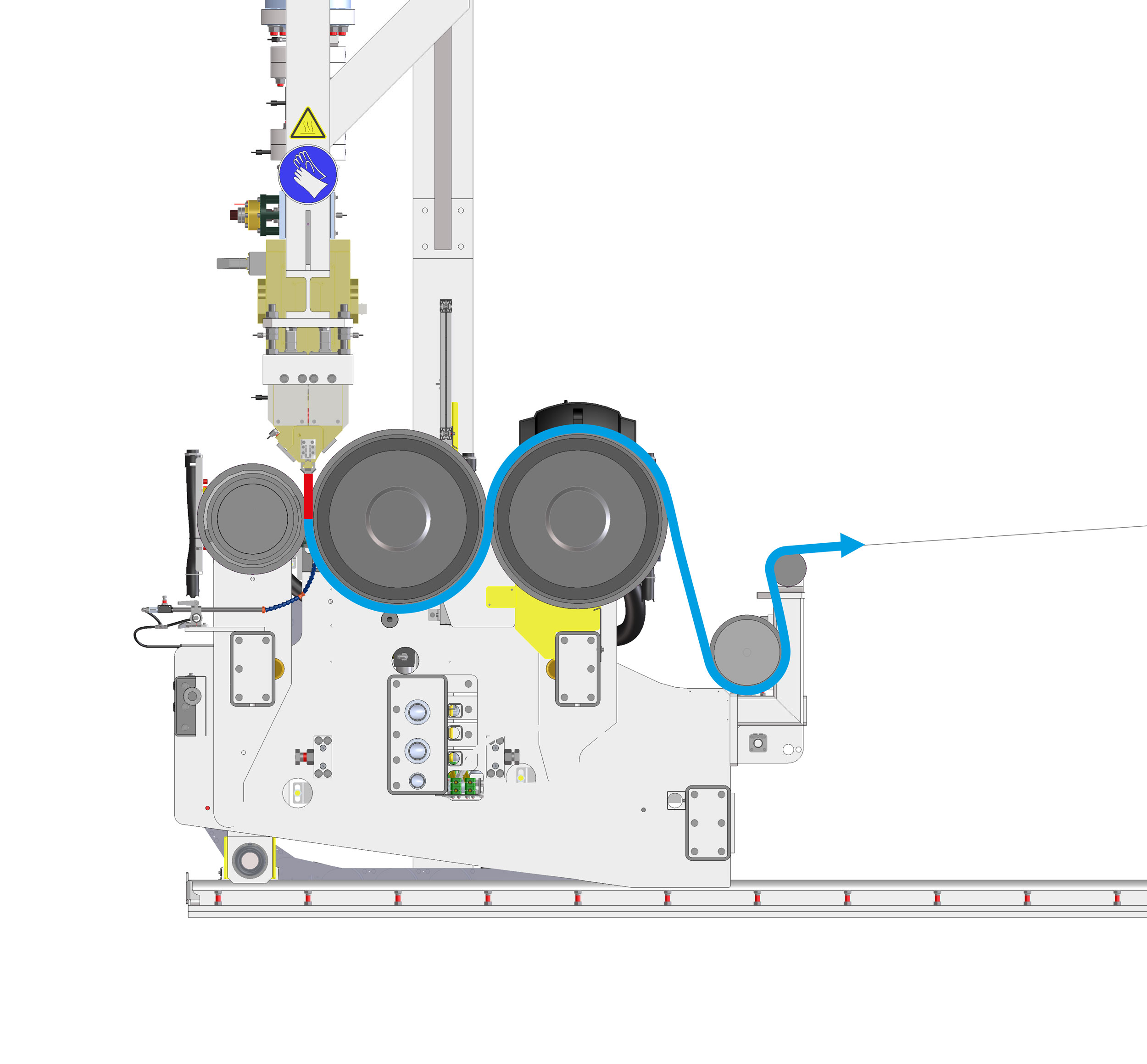

Hy-Roller for ultra-thin PET film: Polishing roll with adjustable crowning

SML is now offering an alternative type of polishing roll that is particularly well suited to the manufacturing of very thin PET films on wider calendering lines. The key characteristic of SML’s new Hy-rollers is the hydraulically adjustable crowning for a perfectly parallel polishing gap.

Forgotten technology revived and upgraded

“The technology of hydraulic roll crowning was developed 20 years ago – and then quickly forgotten. Today we are making use of this concept that will bring significant benefits to our customers,” Julian Leingartner, the CTO of SML, comments. “It would not be SML, if the original version were adopted without thorough redesign. Instead, we took the basic concept, refined it and added some outstanding features for a maximum performance,” Julian Leingartner continues.

Thin calendered films thicknesses with exceptional qualities

With SML’s new Hy-rollers, the variable crowning of the polishing roll is provided by a hydraulic mechanism, which acts on the rolls’ outer shell for controlled expansion along the width of the roll. Due to this mechanism, the polishing roll can exactly follow the surface contour of the cooling roll thus providing a constant gap for the film to be calendered. This enables our customers to produce very thin calendered films with outstanding qualitiy.

Simple in theory – demanding in engineering

Even though the basic principle of the adjustable roll crowning is relatively simple, the design and manufacture of a fully functional roll required thorough FEM calculations and profound engineering skills. For the manufacturers, SML’s new Hy-roller is an opportunity to produce very thin PET film on efficient extra-wide lines with the highest qualities. This can be a particular advantage, when customers attach a high value to downgauging.

Technical characteristics:

- Variable adjustment of roll crowning according to the respective film thickness demands

- Production of thinner films on wide calendering lines

- Perfectly parallel polishing gap – steady roll surface geometry

- Extremely homogenous film quality with very uniform optical properties

Redlham, 10.02.2023