Breadcrumb

More than 280 expert guests at SML Innovation Days 2024

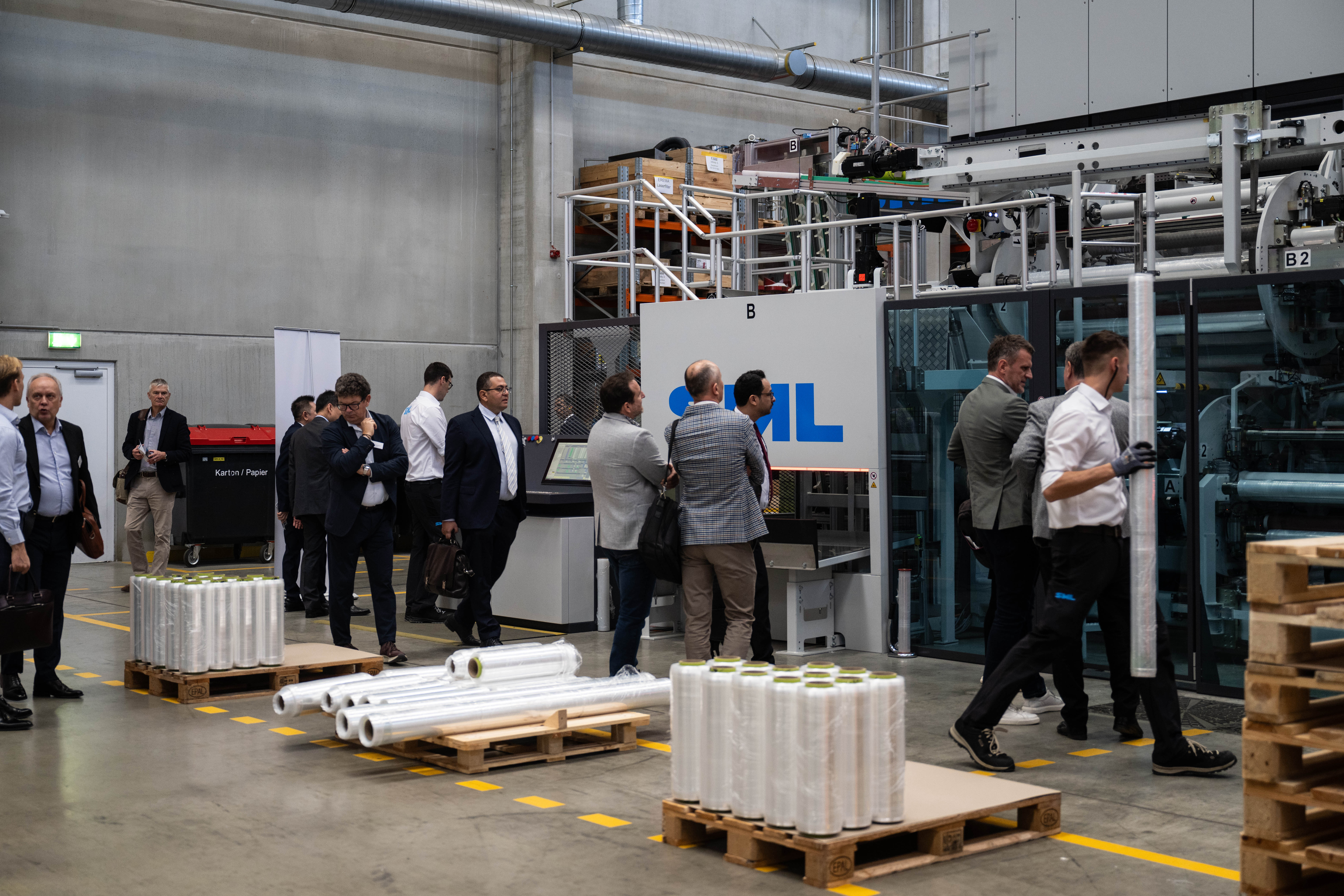

Around 230 customers and 50 representatives from all over the world came to the SML headquarters in Upper Austria on 9 and 10 October 2024 for specialist presentations, expert discussions and live demonstration runs about future trends in extrusion technology.

The topics covered on SML Innovation Days were varied and diverse; they ranged from new technologies for recyclable, flexible packaging to innovative stretch film products, and from coating lines for liquid packaging board to solutions for data-based process optimisation.

Revolutionising mono-material packaging: MDO-PE film as thin as 15 µm

A thickness range from ultra-thin 15 µm to 60 µm, production speeds up to 300 m/min, a perfect thickness profile across the entire film width, and the possibility to manufacture various mono-material PE film types are the main advantages of SML’s latest cast film line with an integrated MDO unit. The line was designed to manufacture MDO-PE film as thin as 15 µm. Naturally in an absolutely stable process, and with no compromises in performance, functionality and printability.

Live Demonstration: Manufacturing mono-material PE structure for stand-up pouches

A highlight at the SML Innovation Days 2024 was the live production of films for easy-to-recycle mono-material stand-up pouches from PE. A highly innovative 17-micron MDO-PE film for the surface layer and a 65 µm CPE sealant film for the stability of the pouch were manufactured on SML’s latest state-of-the-art cast film line with an integrated MDO unit. In a subsequent process, the two films were laminated on a high-performance FlexPack coating and lamination system.

World premier: Inline pre-stretch production live

For the first time, SML presented its inline pre-stretch unit live in operation to a wider public. Integrated in a state-of-the art SmartCast Infinity stretch wrap film line, the market-tested and approved system is setting a new standard for efficiency in production. With the integrated pre-stretch unit, ready-to-sell-products can be manufactured straight from the line. At the end, the inline manufacturing of pre-stretch film means significantly lower production efforts, less space requirements and logistics – and lower costs.

SML EcoCompact II: High-speed winding for 2-m stretch film line

Live demonstration runs were also performed with a 2-m EcoCompact II stretch film line. Visitor interest centred on the high-performance winder W4000-4S 2T. Its short winding shafts make significantly higher production speeds possible. At 2” hand rolls, production speed can be extended to 700m/min and more, leading to a significant increase in output - and line efficiency.

Redlham, 14.10.2024