Breadcrumb

Available now! A demonstration line for 2mm-thick PET sheet

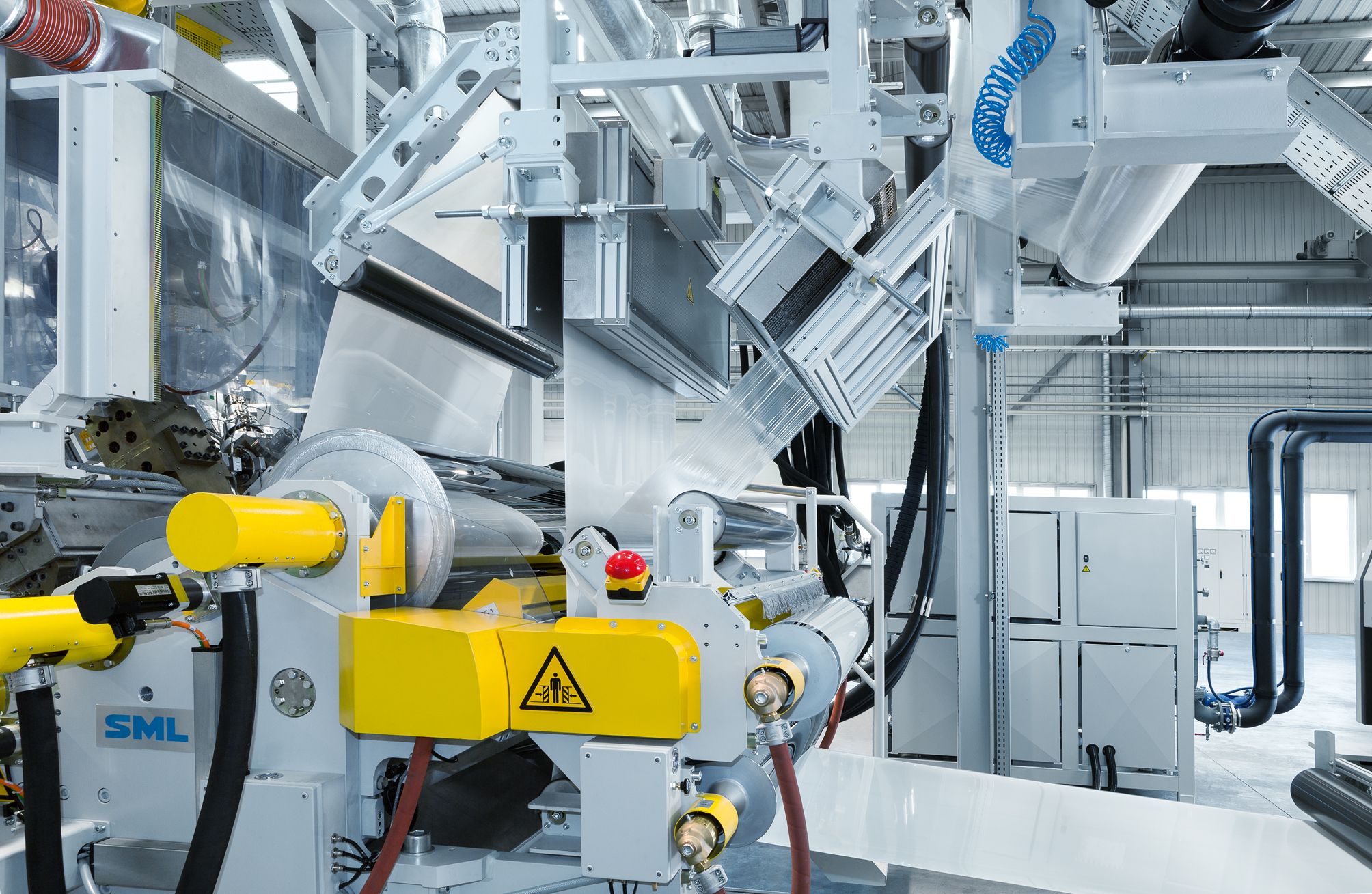

SML recently unveiled an innovative demonstration line for the production of PET sheet in a thickness range of up to 2mm.

The importance of PET as a raw material for countless thermoforming applications is clearly on the rise. Moreover, the market is not only demanding more environmentally acceptable raw materials, which should offer a high degree of recyclability, but also thicker PET sheets. These are to be characterised by high transparency and stiffness, and thereby serve the trend towards even larger clear cups and trays for food packaging.

Producing thick PET sheet with excellent optical properties is a very demanding process. Special attention needs to be paid to the quality of the raw material itself, raw material drying and melt treatment. Accordingly, the design of the entire line and the selected process parameters can improve the properties of thick PET sheet significantly.

The slanted, upstack roll stack mounted on the demonstration line is perfectly suited to thick PET sheet production requirements. Furthermore, on the basis of its vast experience, SML is able to offer advice on optimum process parameters for individual production needs.

Main technical data:

Two extruders for 3-layer A/B/A structures

Thickness range: 0.2 - 2mm

Max. output: up to 1,300 kg/h

Max. sheet width: up to 1,100 - 1,200mm

Reductions in packaging material weight represent another market trend. Therefore, the PET sheet demonstration line is also equipped with a gas injection system for CO2 or N to produce physically foamed PET sheet as an alternative and thereby widen the product portfolio of companies in the thermoforming business. Furthermore, the demonstration line features an IR-lamination system for the production of PET/PE laminates.

Conclusion: rigid PET, PP and PS sheet – possible processes and its advantages

The output of rigid PET sheet with a thickness of up to 2mm stands in the centre of SML’s new demonstration line. One of several possible processes is the production of rigid PET sheet with a foamed center layer. Another key process is the fabrication of rigid PET/PE laminates. A central advantage of the new demonstration line is the output of rigid PET sheet with excellent optical properties, especially for large-sized cups and trays. Another advantage is the very resource efficient production process due to reduced weight and material consumption. All rigid PET sheets from SML’s demonstration line are recyclable.

Beside rigid PET sheet, SML’s demonstration line also produces rigid PP and PS sheet with or without a foamed center layer at a very high quality. As with rigid PET sheet, the production processes of rigid PP and rigid PS sheet are very resource efficient due to reduced weight and material consumption.

All in all, the utmost process flexibility for different applications is guaranteed: Production switches between thick, foamed, or laminated PET/PE sheet as well as between PP and PS sheet can be completed within minimum change-over times.

Lenzing, 30.08.2017