- Cast film lines

- Stretch wrap film lines

Stretch wrap film lines

An intelligent modular system to boost your productivity.

Dynamic markets are most reliant on rapid-fire solutions. That is why we opt for pre-engineered cast film lines in the stretch film segment, which we can optimise to fully suit your needs and your final product.

Our modular system allows for fast delivery and quick commissioning. Innovative engineering and the development of new core components, such as high-speed extruders and stretch film winders, help our customers to successfully position themselves in the highly competitive packaging industry.

Our technology.

It does not matter whether you need to work with small, compact lines or the largest of their kind in the world; whether you require final film widths from 1.5 to 6 metres or films whose layers number as few as 3 or as many as 67. Our stretch film machines can always produce the ideal wrapping film for every type of application.

After all, our special winders are one of the key components in every one of our stretch wrap film lines. There are three different winder models available depending on the requirements of the situation and the desired degree of automation.

Line Types

Small, compact, strong.

MiniCast stretch wrap film line

The SML MiniCast stands out due to its compact design, taking up less than 100 sqm in floor space. It is typically equipped with four extruders creates an output up to 1,050 kg/h with up to 5 layers. The MiniCast lines are prefabricated in small lots, meaning these stretch film lines are available at short notice. The MiniCast is popular among both new market entrants and established manufacturers of niche products, impressing users with its high flexibility and ease of use.

| Products | super power stretch, machine stretch, hand stretch, cling film, silage film |

|---|---|

| Film thickness range | 8 - 50 μm |

| Web width | 3 x 500 mm |

| Film structure | 3 or 5 layers |

| Production speed | up to 650 m/min |

| Film thickness range | 12 µm | 600 kg/h |

|---|---|---|

| 17 µm | 845 kg/h | |

| 23 µm / MiniCast® 3L | 900 kg/h | |

| 23 µm / MiniCast® 5L | 1,050 kg/h |

Unmissable benefits

- Speedy delivery thanks to prefabricated components

- Web width of 1.5 m allows roll widths of 3 x 500 mm or 2 x 750 mm

- Ability to switch between 2” and 3” core diameter

- Coreless

- Modified edges

- ThinCore technology

Winding technology that ensures perfect results.

We can always offer the ideal winder type which meets your needs. In the case of the MiniCast® stretch film line, our winder solutions are the winders W4000-2S and W4000-4S.

Click here to discover our complete range of winders.

Flexible, compact, efficient.

EcoCompact stretch wrap film line

Our EcoCompact is a compact cast film extrusion line

(floor space: 140 m²) that can produce top-quality stretch wrap film while providing maximum flexibility for fast product changes.

This machine gives our customers efficient stretch film production capability with a film width of 2 m and an output rate of up to 1,600 kg/h. The EcoCompact cast film line is particularly well-suited to medium-scale production runs.

| Products | super power stretch wrap film, machine stretch, hand stretch, cling film |

|---|---|

| Film thickness range | 8 - 50 μm |

| Web width | 4 x 500 mm |

| Film structure | 3, 5 or more layers |

| Production speed | up to 750 m/min |

| Film thickness range | 12 µm | 800 kg/h |

|---|---|---|

| 17 µm | 1,125 kg/h | |

| 23 µm | 1,200 kg/h |

The benefits at a glance:

- 4 x 500 mm or 5 x 400 mm wide rolls

- Ability to switch between 2” and 3” core diameter

- Coreless

- Modified edges

- ThinCore technology

Winders that ensure perfect results.

We can always offer the ideal winder type which meets your needs.

In the case of the EcoCompact, our winder solutions are the winders W4000-2S, W4000-4S and W3000-4S. Click here to discover our complete range of winders.

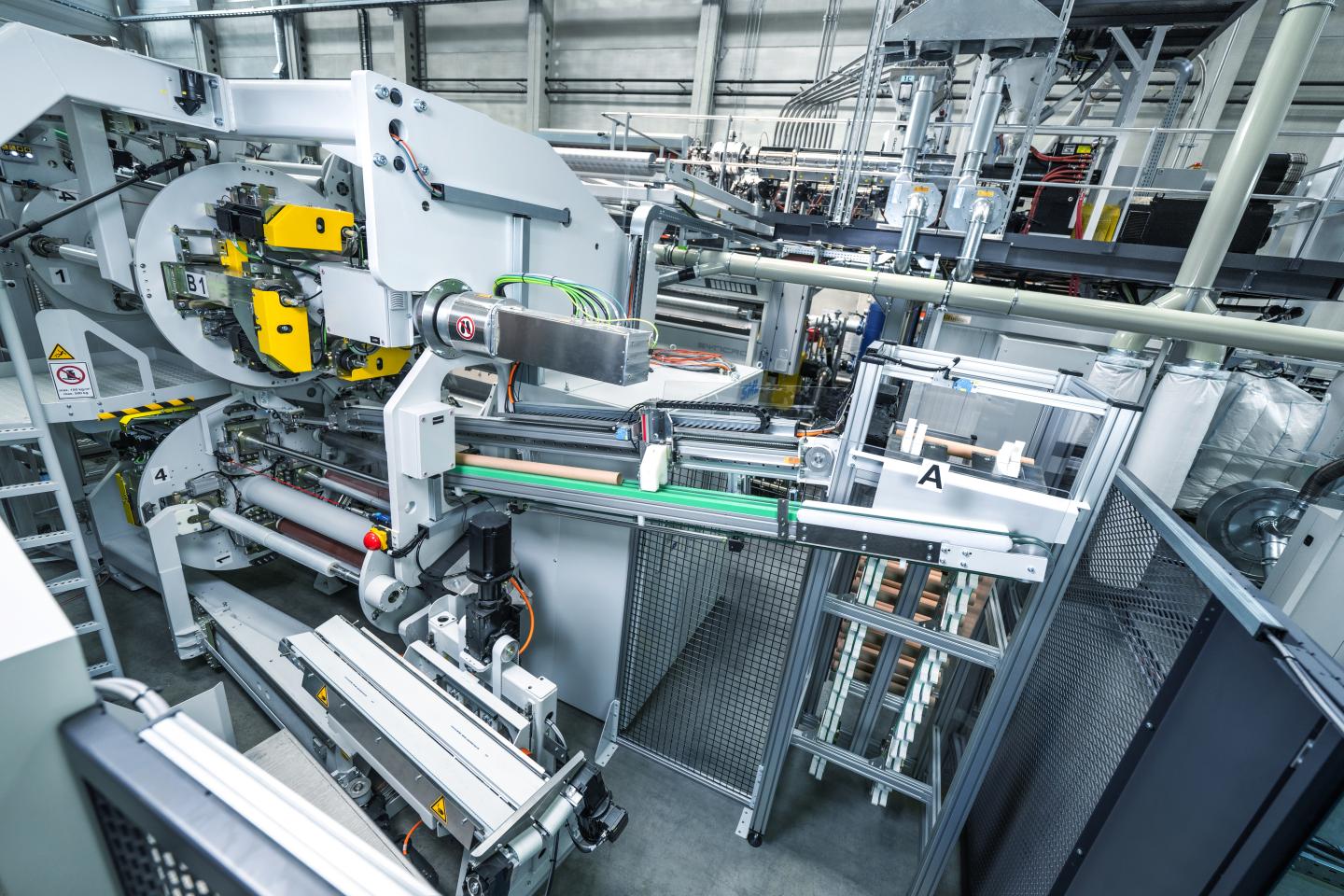

Modular, flexible, powerful.

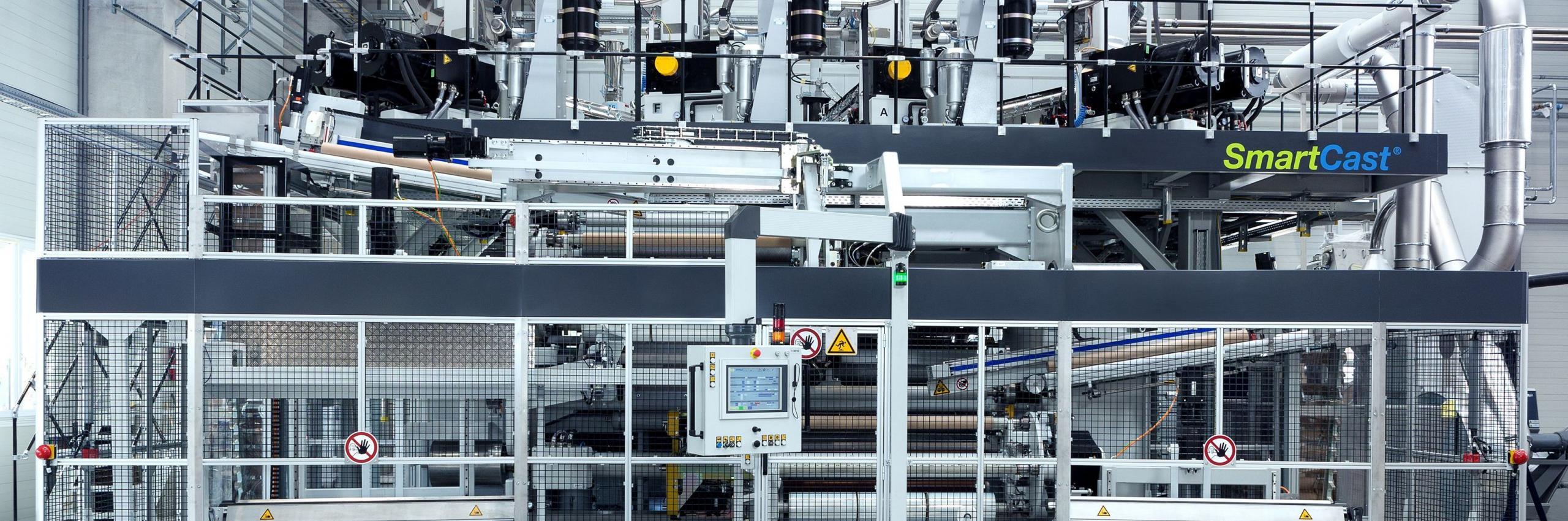

SmartCast stretch wrap film line

The modular stretch film machine offers the perfect combination of high output and great flexibility.

It is remarkable for its four pre-configured extruder groups (with output of between 1,900 and 3,000 kg/h) and the choice available between five, seven or more layers, enabling it to meet almost all customers’ requirements.

One special highlight is its chill roll unit with positioning system. This makes the casting position 100 % reproducible, guaranteeing that all the process parameters can be repeated to perfection at all times.

| Products | super power stretch, machine stretch, hand stretch, cling film |

|---|---|

| Film thickness range | 8 - 50 μm |

| Final web width | 6 x 500 mm |

| Film structure | 5, 7 or more layers |

| Production speed | up to 750 m/min |

| SmartCast®: Film thickness range | 12 µm | 1,400 kg/h |

|---|---|---|

| SmartCast® XL: Film thickness range | 17 µm | 2,000 kg/h |

| 23 µm | 2,400 kg/h |

Benefits that make SmartCast the clear choice:

- Film width of 3m allows 6 x 500 mm or 4 x 750 mm roll applications

- Ability to switch between 2” and 3” core diameter

- Coreless

- Modified edges

- ThinCore technology

Winders that ensure perfect results.

We can always offer the ideal winder type which meets your needs.

In the case of the SmartCast, our winder solutions are double turret winders W4000-2S and W4000-4S or the winder W3000-4S.

Click here to discover our complete range of winders.

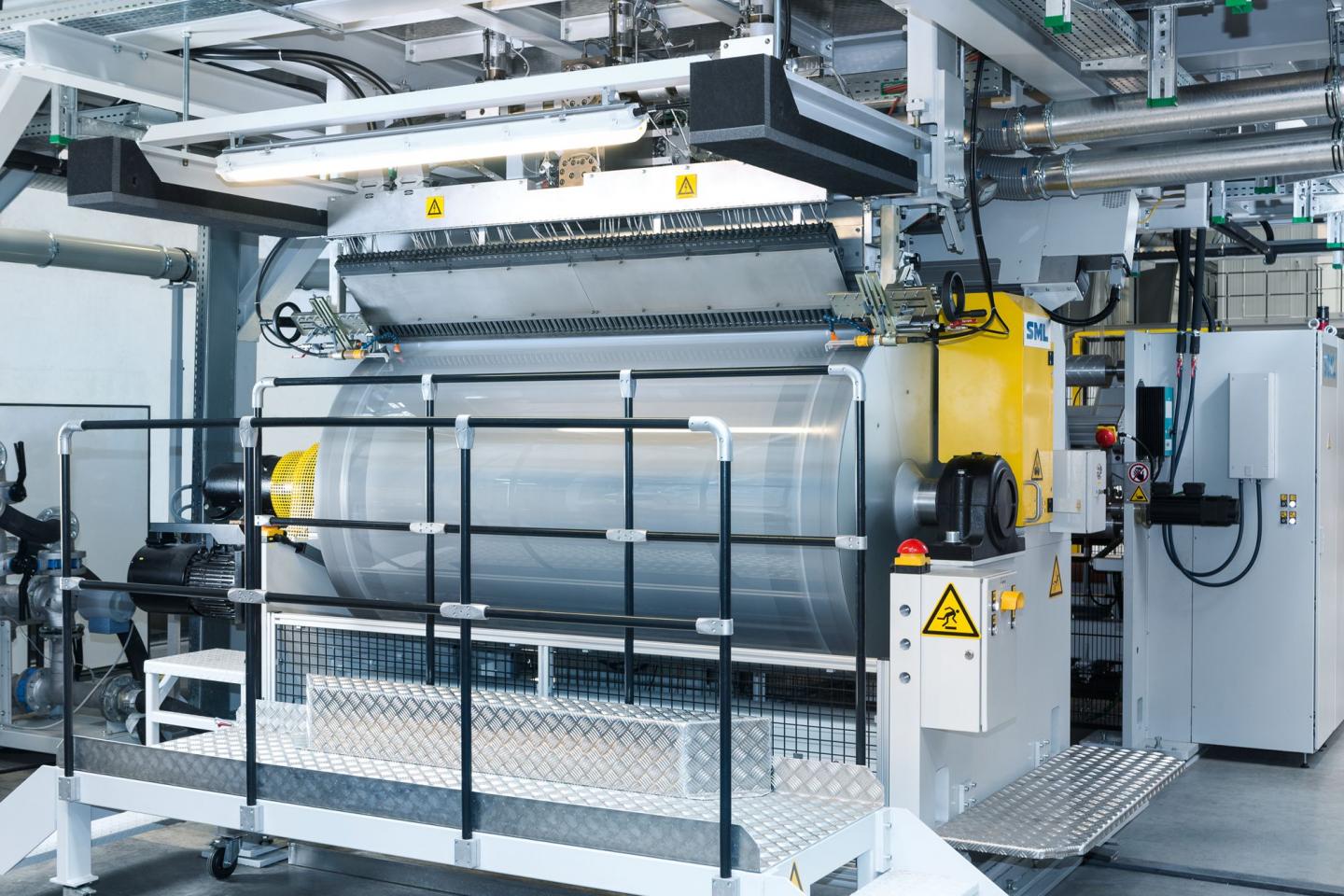

Where high quantity meets top quality.

PowerCast stretch wrap film line

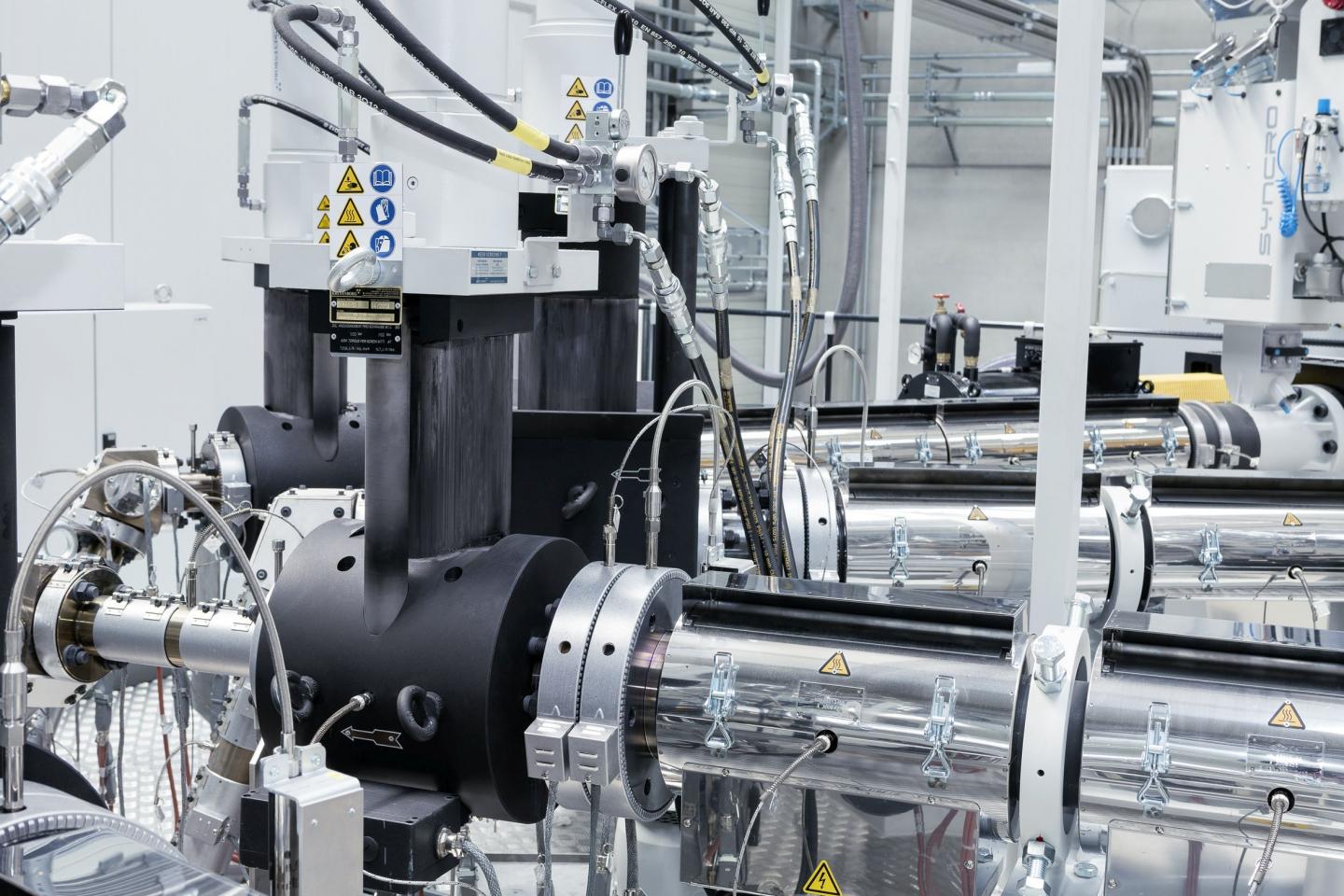

Our PowerCast is an ultra-high-performance stretch film extrusion line that is perfectly suited to the market’s needs in terms of quality and quantity.

Whether with 7 layers or 67, its output rate will be between 2,400 and 3,800 kg/h with three pre-configured extruder groups. These stretch wrap machines stand out due to their unrivalled flexibility in production and ability to handle film widths of 4 or 4.5 m. It was the first cast film line in the world featuring a chill roll unit which has a diameter of 1,600 mm. In short, the PowerCast is engineered for perfect production results.

| Products | super power stretch, machine stretch, hand stretch, cling film |

|---|---|

| Film thickness range | 8 - 50 μm |

| Final web width - PowerCast | 8 x 500 mm, 9 x 450 mm, 10 x 400 mm |

| Final web width - PowerCast XL | 6 x 750 mm, 9 x 500 mm, 10 x 450 mm, 11 x 400 mm |

| Film structure | 7 - 67 layers |

| Production speed | up to 850 m/min |

| PowerCast | 12 µm | > 2,000 kg/h |

|---|---|---|

| 23 µm | 3,400 kg/h |

Benefits only offered by a PowerCast:

- 4m stretch film machine allows for 4 x 1,000, 8 x 500, 9 x 450 or 10 x 400 mm roll applications

- Modified edges

- ThinCore technology

Winding technology that ensure perfect results.

We can always offer the ideal winder type which meets your needs.

In the case of the PowerCast®, our winder solutions are the triple-turret winders W4000-2S and W4000-4S.

Click here to discover our complete range of winders.

In a production class of its own.

MasterCast stretch wrap film line

SML is raising the bar in stretch wrap film production with its MasterCast, the largest cast film extrusion line of its type, which stands out by virtue of its enormous output. The SML MasterCast is unique in the world, with a width of 6 metres and an extrusion capacity of up to 5,000 kg/h.

As a result, it can scale unprecedented heights in terms of investment cost per kilogram of output, reduced labour costs and optimum energy consumption, making it one of the world’s most efficient systems.

| Products | super power stretch, machine stretch, hand stretch |

|---|---|

| Film thickness range | 8 - 50 μm |

| Final web width | 12 x 500 mm |

| Film structure | 5 or 7 layers |

| Production speed | up to 650 m/min |

| Film thickness range | 12 µm | 2,400 kg/h |

|---|---|---|

| 17 µm | 3,300 kg/h | |

| 23 µm | 4,000 kg/h |

Benefits as unique as the MasterCast stretch film line itself:

- 6 m film web width

- 5 and 7-layer versions

- Output of up to 5,000 kg/h

Winding technology that ensures perfect results.

We can always offer the ideal winder type which meet your needs. In the case of the MasterCast, the solution are our fully automatic triple-turret winders W4000-2S and W4000-4S.

Click here to discover our complete range of winders.