Breadcrumb

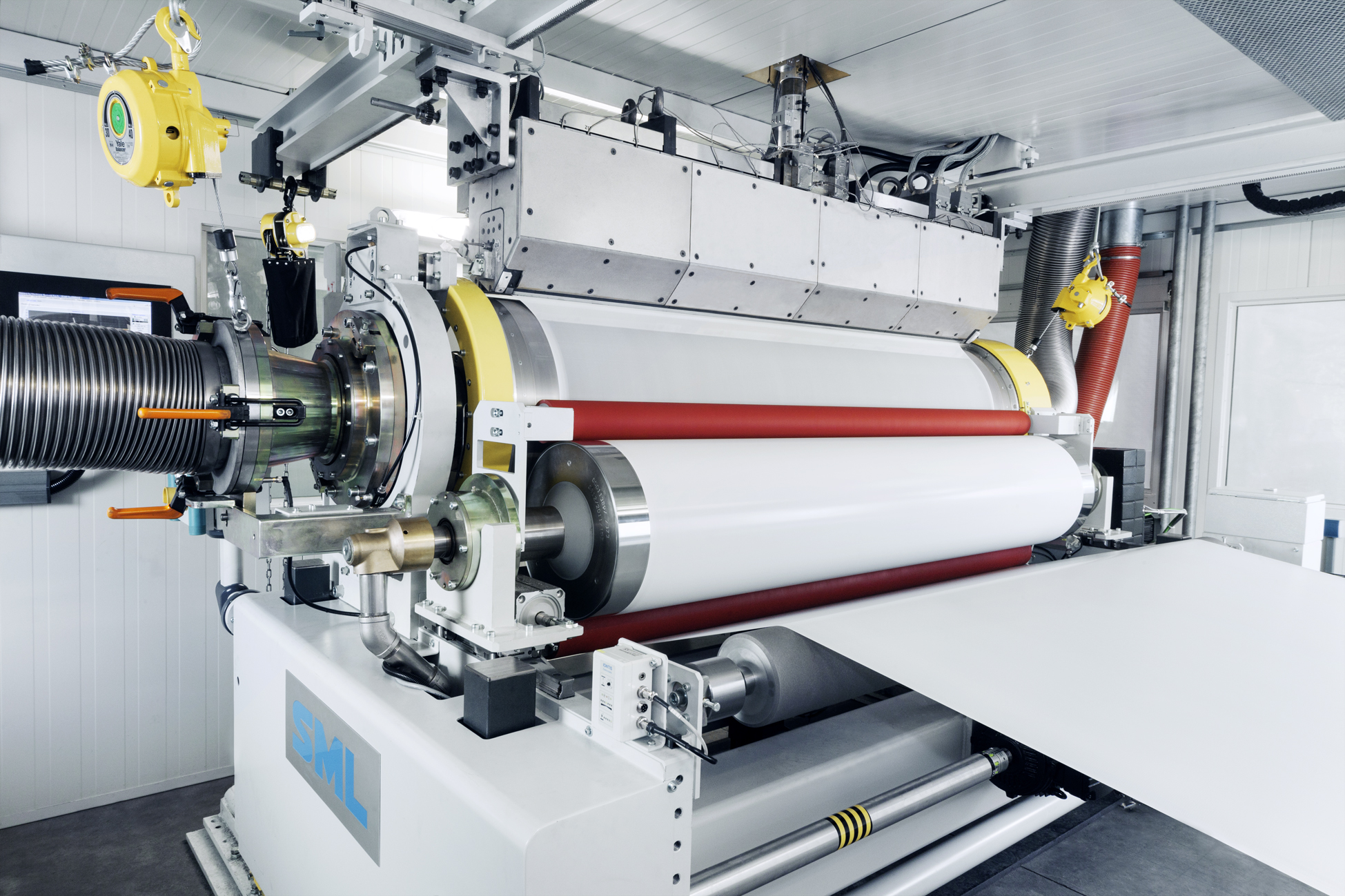

SML starts-up TopSheet Cast Hygiene Line for inline production of high-grade vacuum-perforated film

SML’s TopSheet Cast Hygiene Line is designed for the efficient inline-production of perforated topsheet mono-layer PE film in high volumes. The film is essential in products like panty liners, baby diapers, incontinence diapers as well as food packaging and other medical applications.

The key advantages of the inline-production over the conventional offline processes are:

- Lower energy consumption

- Higher production speeds

- Greater film grammage flexibility

- Increased output

- Improved thickness profile

- Full edge trim recovery

Compared to offline processes, in SML’s TopSheet Cast Hygiene Line the melt curtain emerging from the die is cast on a perforated sleeve with a vacuum chamber inside. By means of the vacuum, tunnel-shaped holes are created in the film. The film is cooled by an additional cooling roller.

Technical basics:

- Film structure: mono-layer PE film

- Film grammage range: 15 - 35 g/sqm

- Final film width: 1,600mm

- Max. mechanical line: speed 200 m/min

Redlham, 31.03.2020