- Technology Centre

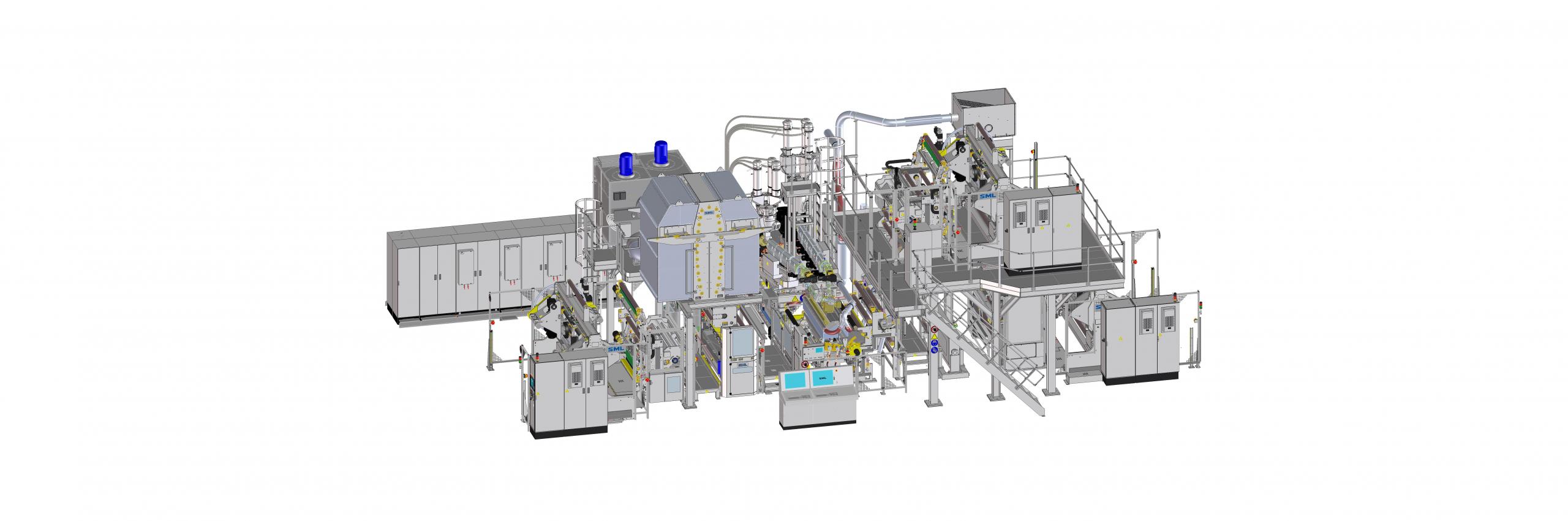

Technology Centre

Creating solutions together.

Our engineers and technicians relentlessly strive to craft the best solution for our customers. No matter the task or challenge you have in store for us, we will work together with you at the Redlham pilot plant to develop ideal solutions that go above and beyond the latest industry standards.

A wide variety of lines from our product groups are available to demonstrate and try out on site.

Типы линий

Coextrusion Lab Sheet Line for PET (PP, PS) sheets

Possibilities to see the line: after week 30/2019

Technical data

| Final film with | 1,100 - 1,200mm |

|---|---|

| Max. mechanical line speed | 70 m/min |

| Thickness range (PET) | 200 – 2,000µm |

| Layer structure | A/B/A or A/B A layer 5-10% |

Line Configuration

| Extruder A | 57/33 L/D |

|---|---|

| Extruder B (Gas injection system for extruder B N2 and Co2) | 135V/37 L/D |

| Rollstack | Slanted roll arrangement | 1,400mm |

|---|---|---|

| Winding System | Max. winding diameter | 1,300mm |

Possibilities to see the line: from week 24/2019

Line ready for customer test runs: approx. from week 27/2019

Technical Data

| Substrate width | 750 – 1,650mm |

| Max. mechanical speed | 450 m/min |

Line Configuration

| Extruder A | 90/33 L/D |

| Extruder B | 60/33 L/D |

| Feedblock and die | 3 layers | |

| Automatic flat die with EBR deckling | 1,850mm | |

| Ozone Treatment | ||

| Corona Treatment for Substrates | ||

| Primer Coating Unit | ||

| Hotmelt Coating Equipment | Equipment for hotmelt Lamination and DoubleCoat process (modul exchangeable with standard pressing module on laminator) | |

| Thickness measuring Unit | Kr-85 | |

| Edge Trimming | With shear cut system | |

| Laminating Unit | Chill roll diameter | 800mm |

| Winding Unit | Fully automatic shaftless turret winder | |

| Max. mechanical winding diameter | 1,270mm | |

| Unwinding Units #1 and#2 | Fully automatic turret unwind, shaftless | |

| Max. mechanical unwinding diameter | 1,270mm |

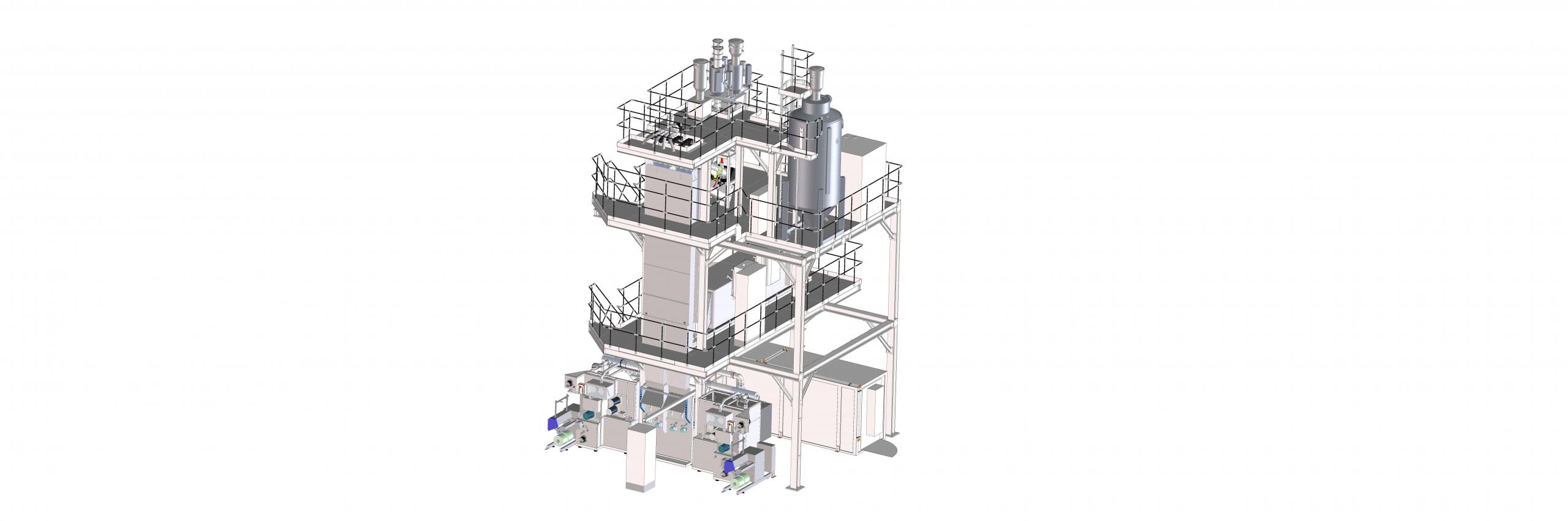

BCF PET/PA6/PP 4x2 TWIN (as laboratory configuration)

Possibilities to see the line: On consultation with SML R&D or Sales Department

Technical Data

| BCF Yarn | |

|---|---|

| Titer Range | 1,000 – 5000dtex |

| Output capacity | PET 200 kg/h |

| PA6 and PP 160 kg/h | |

| Applications | Mainly carpet and also niche products |

Line Configuration

| Raw material handling | Granule drying | |

| Dosing and mixing device | ||

| Extrusion | Extruder diameter | 75mm |

| Spinning | Electrically heated, temperature controlled spinning head | |

| Quenching | With speed, temperature and air humidity control | |

| Drawing section | Number of drawing steps | 1 |

| Number of texturing units | 1 | |

| Winding | Automatic high speed winder | |

| Threads per winder 1 | 2 | |

| Threads per winder 2 | 3 | |

| Production speed | 3,000 m/min |

Austrofil Spinning Line FDY

Possibilities to see the line: On consultation with SML R&D or Sales Department

Technical Data

| Endproducts | Fully, middle and partial drawn yarn, especially for PP and many other resins |

| Titer range (standard) | 150 – 4,000dtex |

| Output capacity | PP 160 kg/H |

| Applications | Textile and technical applications |

Line Configuration

| Raw material handling | Granule drying | |

| Dosing and mixing device | ||

| Extrusion | Extruder Diameter | 75mm |

| Spinning | Electrically heated, temperature controlled spinning head | |

| Quenching | With speed and temperature control | |

| Drawing Section | Number of drawing steps | 2 |

| Winding | Automatic high-speed winder | |

| Threads per winder | 2 or 4 | |

| Production speed | 3,000 m/min |

SML is so much more

Press Releases

Service