Breadcrumb

A new MDO boosts productivity

SML is known in the global plastics, packaging and hygiene industries as a developer of innovative, high-performance extrusion lines that offer enhanced quality and productivity.

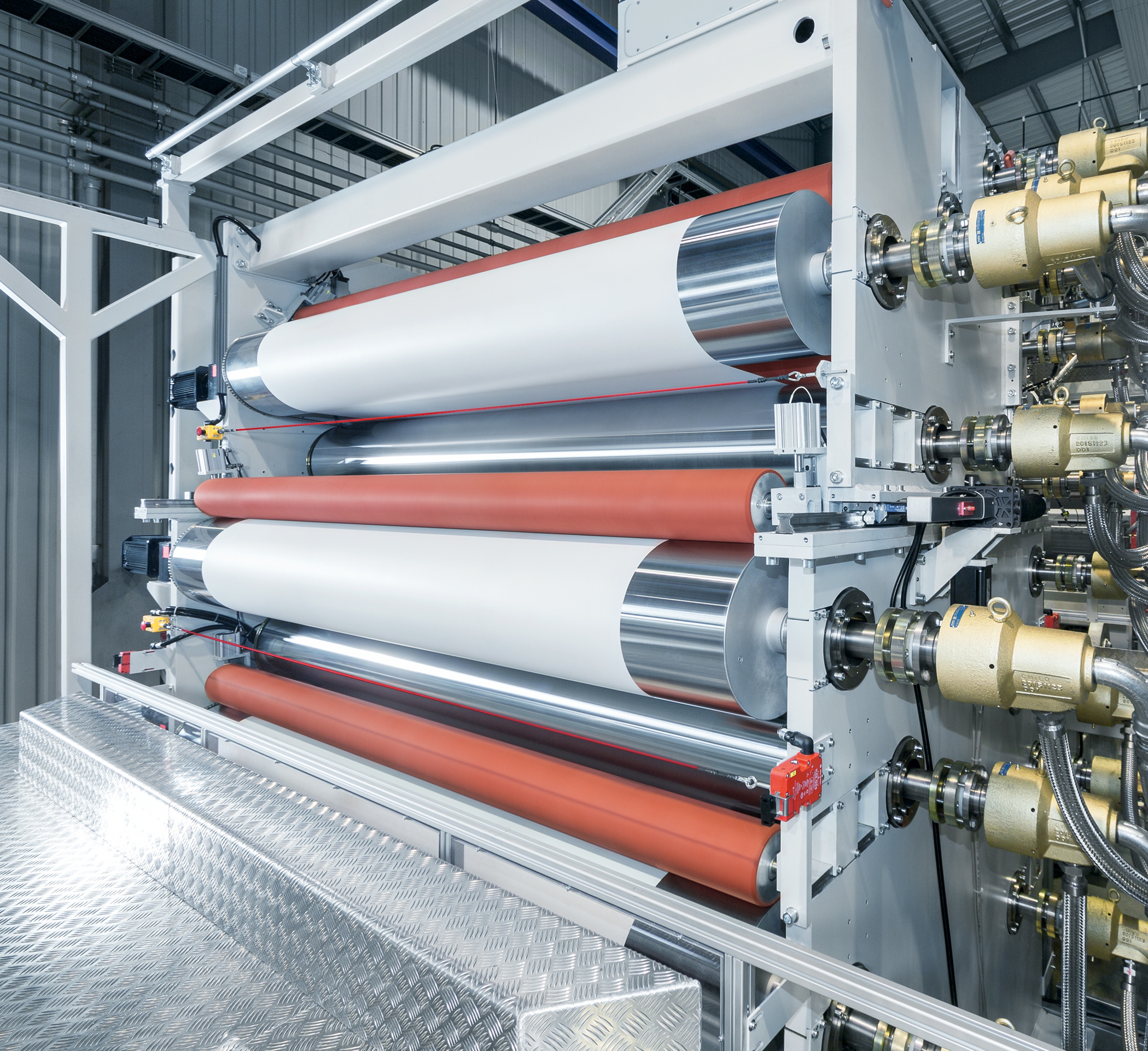

SML’s newly designed mono-axial direction orientation unit (MDO) for both cold and hot stretching typifies this approach. Its main advantage lies in its ability to control film properties through the inline variation of the stretching gap between 70 and 350mm using a servomotor. This is significant because the best PP and PE film characteristics result with a shorter gap, while a longer gap is required when stretching PET film.

The diameter of the stretching rollers has been increased to 250mm and the preheating, stabilising and cooling rollers now have diameters of 400mm. These dimensions are suitable for widths of up to 4.3m. In addition, the rollers are installed in side frames, which ensure vibration dissemination into the foundations even at high speeds. In addition, production flexibility is guaranteed because all rolls are driven and temperated separately.

The MDO is ideal for the production of minimum film thicknesses of 10gsm and thereby mirrors the trend towards thinner films. Its suitability for large widths and high speeds also constitutes an important cost and efficiency factor. Moreover, an increase in mechanical speed to 500 m/min boosts productivity and a switch to an A-frame machine layout allows easier maintenance and cleaning.

In short, stretching using SML’s innovative MDO technology means greater production speeds and output in combination with highest process stability.

Lenzing, 14.06.2017