Breadcrumb

Foamed PET sheet production employing a concial twin screw extruder

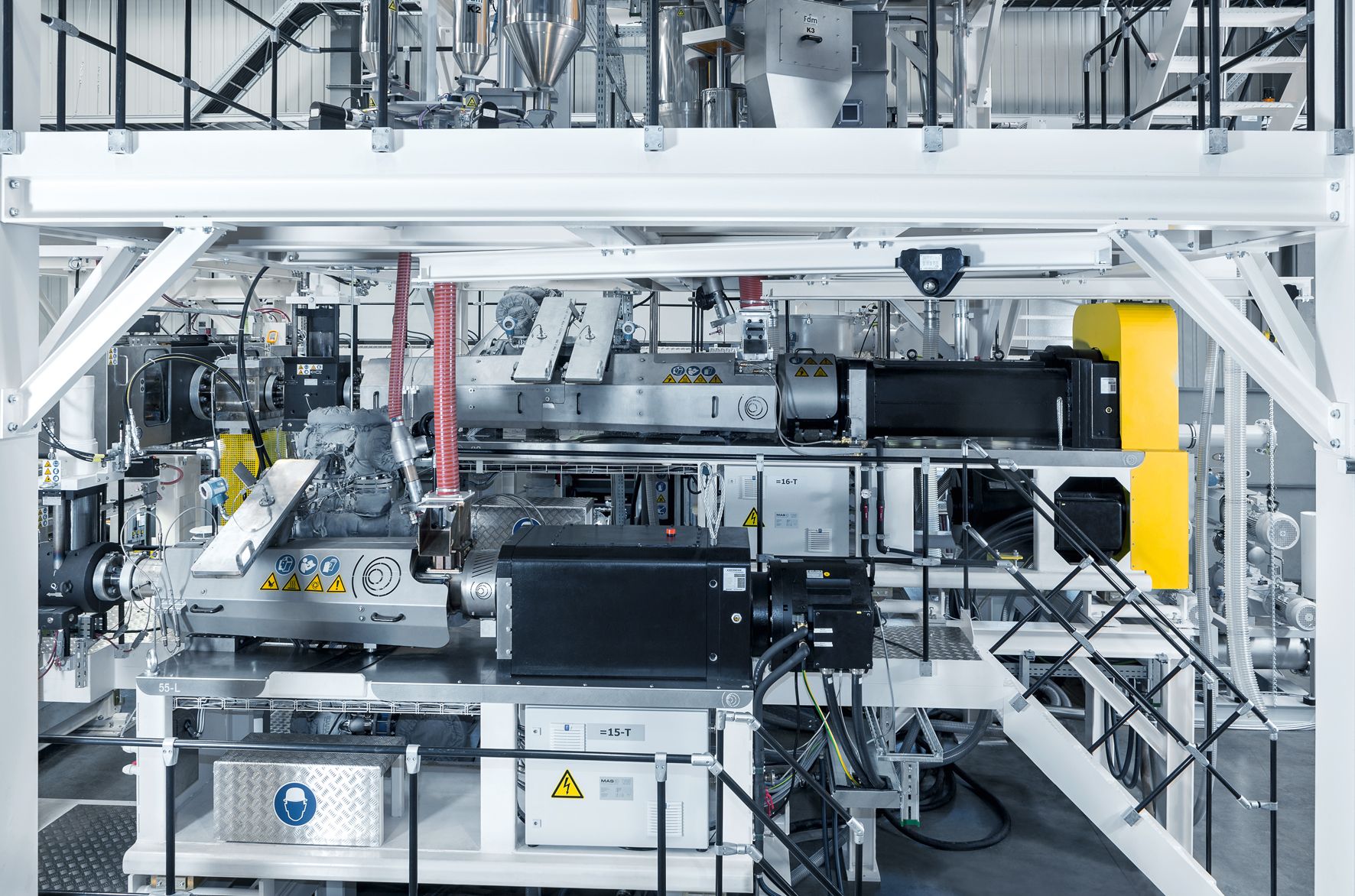

Physical foaming with a single-screw extruder is already a well-known process, but the production of physically foamed PET sheet using a conical twin-screw extruder is a completely new and highly successful SML development.

For physically foamed PET it is necessary to give special attention to melt treatment. Thus, SML gave highest priority to this topic when designing the extrusion equipment for melt preparation. The newly developed FlexiPET sheet line is equipped with a 90mm conical twin screw extruder for an output of max. 1.4 to/h. One essential advantage of the conical twin screw extruder is the very big inlet opening which makes this extruder perfect for processing of high percentage of regrind, even with low bulk density.

Moreover, it represents just one of the applications of SML’s FlexiPET sheet line, which can handle production switches between foamed sheet, solid sheet, cast film or laminated PET/PE with minimum change-over times.

To learn more about this new development our specialists will be available for detailed information in in Düsseldorf: SML at K'2016 I Stand No. 17C42

Lenzing, 10.10.2016